The CSB is planning to investigate an explosion in a carbide plant in the US, that occurred on Tuesday. Two employees were killed in the incident. A news report mentions that

"Located along the Ohio River in West Louisville, the plant is part of a petrochemical complex dubbed Rubbertown. It makes calcium carbide products, which are used in metal fabrication and construction.

The initial explosion occurred around 5:40 p.m. Monday and involved calcium-carbide — a flammable compound that combined with water produces unstable acetylene gas, Hamilton said. The second explosion happened when one of three transformers that contained mineral oil above the original blast caught fire, officials said."

The workers who died were longtime employees who worked in the furnace department where the explosion occurred, said plant general manager John Gant. Jorge Medina, 56, of Louisville, died at University Hospital early Tuesday morning with third-degree burns over 90 percent of his body. An autopsy is planned for Steven Nicholas, 59, of Charlestown, Ind., who died Monday".

March 23, 2011

March 22, 2011

Fire in lift kills two persons

Thanks to Mr Sreedharan for sending information about a fire accident in a plant when two workers died in a fire in a lift when they were carrying combustible material. According to the news item, "the workers were carrying improperly packed medicine ‘CBS' which released a vapour which is combustible in nature. The vapour released was in large quantity leading to fire in the lift burning them alive. By the time the other workers in the factory arrived and tried to out the fire, both the casual workers were burnt alive".

Read the article in this link

I had earlier posted an incident where a lab technician in a plant (the Lab was located in the control room building) was taking a bottle of solvent and using the lift (elevator) when he accidentally dropped the bottle. The solvent went down the elevators floor and collected in the well. A spark ignited the solvent and the person had to be rescued from the elevator.

Read the article in this link

I had earlier posted an incident where a lab technician in a plant (the Lab was located in the control room building) was taking a bottle of solvent and using the lift (elevator) when he accidentally dropped the bottle. The solvent went down the elevators floor and collected in the well. A spark ignited the solvent and the person had to be rescued from the elevator.

How do we make PSM work in India?

PSM is an administrative control over process safety. The elements may vary from 14 to 30 and above but finally it is an administrative control. Human beings take decisions that can have an effect on PSM. For example, the CSB has released the safety video of the Bayer Crop science explosion where it mentions an interlock was bypassed by operators with the knowledge of the manager. Whatever systems you have, there will be a time, when under pressure for production, mistakes can happen and the administrative control fails. Behaviour based safety, developing process safety culture, operational discipline all are dependent on the Human Being. Especially the ones at the top…

Why do the same mistakes keep happening over and over again? It’s because of a basic human trait ….. if nothing has happened for so many years, one does not expect to see anything bad in the future, too.

What you do not see may cost you terribly!! Whose job is it to see that the human being at the operational level does not deviate from set procedures? It’s the job of the top management. But it’s a chicken and egg situation. Today’s top management in Chemical Plants are under severe pressure themselves and often loose sight of what is going on at the ground level. Whenever a new system that brings in top management involvement is implemented, I often see, that initially, everything is working all right and top management are focused on process safety. As time gets by, and people (including top management) and priorities change, the effectiveness of PSM changes, too. I feel that the only way to make PSM work is through effective legal enforcement. In this connection, I am happy to see in the CSB video that the Costa County officials have been able to bring down incidents by effective auditing of PSM systems.

I do not see this happening in India where PSM is not even Mandatory! Let’s not wait for another Bhopal to occur. Do write in your comments.

March 21, 2011

Cost - Benefit trade off and risk

An editorial in Las Vegas Review Journal highlights the need for facility siting, inherent safer design and cost benefit trade off Vs Risk. The article mentions the following:

"It's not too early to start asking the billion-dollar questions: Is it possible to build nuclear reactors that can be relied on to safely shut themselves down, using passive cooling systems dependent on gravity rather than electric pumps, during an earthquake of such magnitude? Of the 442 nuclear reactors in operation around the world today, the World Nuclear Association estimates 20 percent are located in areas of "significant seismic activity." Siting will be re-examined. Better designs do appear possible.

One hundred percent passive cooling systems are not yet commercially available. But had even a partial passive system been in place at the Fukushima Dai-ichi plant, Japan's current nuclear crisis could have been averted, argues John McGaha, a board member of the American Nuclear Society.

"The thing that got Japan in trouble was not the earthquake, but the tsunami that took out power supplies," Mr. McGaha says. "Passive reactors would have been part of the answer to what happened."

In General Electric's design for the Fukushima reactors, the cooling tanks for storage of spent fuel rods sit atop the containment buildings. Some of these tanks appear to have gone dry, leaving the spent rods to spew radiation. If the tanks sat at or below ground level, they could be refilled by simply opening a spigot from backup water tanks, or through gravity-fed pipelines.

Meantime, the backup diesel generators that might have averted the disaster were positioned in a basement, where they were overwhelmed by the tsunami. In the end, cost-benefit trade-offs will still be made. But a valid cost-benefit analysis requires data as to what the true "costs" are when systems fail."

Read the editorial in this link..

"It's not too early to start asking the billion-dollar questions: Is it possible to build nuclear reactors that can be relied on to safely shut themselves down, using passive cooling systems dependent on gravity rather than electric pumps, during an earthquake of such magnitude? Of the 442 nuclear reactors in operation around the world today, the World Nuclear Association estimates 20 percent are located in areas of "significant seismic activity." Siting will be re-examined. Better designs do appear possible.

One hundred percent passive cooling systems are not yet commercially available. But had even a partial passive system been in place at the Fukushima Dai-ichi plant, Japan's current nuclear crisis could have been averted, argues John McGaha, a board member of the American Nuclear Society.

"The thing that got Japan in trouble was not the earthquake, but the tsunami that took out power supplies," Mr. McGaha says. "Passive reactors would have been part of the answer to what happened."

In General Electric's design for the Fukushima reactors, the cooling tanks for storage of spent fuel rods sit atop the containment buildings. Some of these tanks appear to have gone dry, leaving the spent rods to spew radiation. If the tanks sat at or below ground level, they could be refilled by simply opening a spigot from backup water tanks, or through gravity-fed pipelines.

Meantime, the backup diesel generators that might have averted the disaster were positioned in a basement, where they were overwhelmed by the tsunami. In the end, cost-benefit trade-offs will still be made. But a valid cost-benefit analysis requires data as to what the true "costs" are when systems fail."

Read the editorial in this link..

March 20, 2011

Description of some damages to the Nigata Nuclear plant in 2007 - Courtesy TEPCO

The earthquake at Nigata, Japan in 2007 was 6.9 on the Richter scale. The one that hit Fukushima was 8.9.(The Richter scale is Logarithmic!!!) See the damages caused by the Nigata earthquake...

"Displacement of the ducts connected to the main exhaust stack (units 1 to 5)'. Courtesy of The Tokyo Electric Power Company, Inc

Courtesy of The Tokyo Electric Power Company, Inc

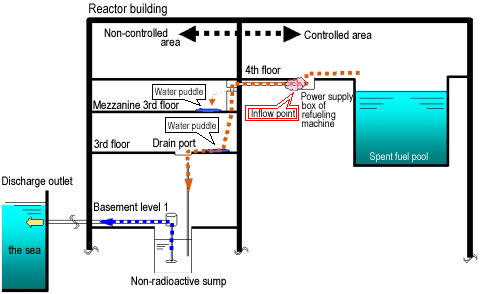

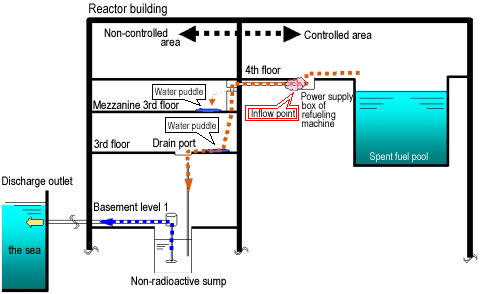

"Leakage of water containing a trace of radioactivity into the sea via the non-controlled area of unit 6.

The seismic motion caused the overflow of water from the spent fuel pools in units 1 to 7. At unit 6, the overflowed water leaked into the non-controlled area via the electric cable conduit of the refueling machine and flowed into the sump. It was confirmed that water in the drainage sump had been discharged into the sea by the sump pump when the water level increased. (Refer to the figure below".)

Courtesy of The Tokyo Electric Power Company, Inc

Courtesy of The Tokyo Electric Power Company, Inc

Iodine and radioactive particulate materials were detected at the main exhaust stack of unit 7.

"When the earthquake occurred, unit 7 was automatically shut down. However, it was confirmed that since the gland steam ventilator continued to operate for a while, the steam sealing the shaft was exhausted, and subsequently radioactive steam left in the turbine had flowed out to through the gland steam ventilator. (This event was reported on July 16th.)

During normal operation, the turbine shaft is covered with the gland steam (containing no radioactive material) so that the steam containing radioactive materials sent from the reactor to the turbine does not flow out from the turbine through the gland steam ventilator.

Impact to the Environment

The radioactivity of radioactive iodine and radioactive particulate materials released to the environment through the main exhaust stack was about 4 × 108 becquerels and 2 × 106 becquerels, respectively. The dose by this radioactivity was 2 × 10-7 millisieverts, an equivalent to about one 10 millionth of the dose (2.4 millisieverts) an average person is exposed to from natural sources annually.

No radioactive material has been detected since the gland steam ventilator was stopped on July 19th".

For more details visit the TEPCO site in this link

"Displacement of the ducts connected to the main exhaust stack (units 1 to 5)'. Courtesy of The Tokyo Electric Power Company, Inc

Courtesy of The Tokyo Electric Power Company, Inc

"Leakage of water containing a trace of radioactivity into the sea via the non-controlled area of unit 6.

The seismic motion caused the overflow of water from the spent fuel pools in units 1 to 7. At unit 6, the overflowed water leaked into the non-controlled area via the electric cable conduit of the refueling machine and flowed into the sump. It was confirmed that water in the drainage sump had been discharged into the sea by the sump pump when the water level increased. (Refer to the figure below".)

Courtesy of The Tokyo Electric Power Company, Inc

Courtesy of The Tokyo Electric Power Company, Inc

Iodine and radioactive particulate materials were detected at the main exhaust stack of unit 7.

"When the earthquake occurred, unit 7 was automatically shut down. However, it was confirmed that since the gland steam ventilator continued to operate for a while, the steam sealing the shaft was exhausted, and subsequently radioactive steam left in the turbine had flowed out to through the gland steam ventilator. (This event was reported on July 16th.)

During normal operation, the turbine shaft is covered with the gland steam (containing no radioactive material) so that the steam containing radioactive materials sent from the reactor to the turbine does not flow out from the turbine through the gland steam ventilator.

Impact to the Environment

The radioactivity of radioactive iodine and radioactive particulate materials released to the environment through the main exhaust stack was about 4 × 108 becquerels and 2 × 106 becquerels, respectively. The dose by this radioactivity was 2 × 10-7 millisieverts, an equivalent to about one 10 millionth of the dose (2.4 millisieverts) an average person is exposed to from natural sources annually.

No radioactive material has been detected since the gland steam ventilator was stopped on July 19th".

For more details visit the TEPCO site in this link

March 19, 2011

Process Safety and Proposed changes to Indian Factories act

A news article in the Business Standard mentions the proposed changes to the Indian Factories Act. There are two proposed modifications, which I think may have an effect on process safety:

"The proposed changes to Section 64 and 65 of the Act, which deal with overtime working hours in factories, says the hours will be increased to 100 from the existing 50.

The proposals also seek to shift the blame for industrial accidents from the proprietor to the manager of a factory provided it is government-owned, by changing the definition of “occupier” of the factory in Section 2 (n) from the “person who has ultimate control over affairs of a factory” to the “person appointed to manage the factory”.

Workers who are working more hours of overtime are prone to making mistakes. There is a growing shortage of experienced qualified chemical plant operators in India and the proposed increase in overtime hours may affect process safety. The second proposed change of transferring accountability for Government owned companies to the person appointed to manage the factory may lead to a situation where the unit head in a government owned factory may resign when he or she finds things are not going his/her way with regard to process safety. This will lead to a discontinuity in managing process safety.

Read the article in this link.

"The proposed changes to Section 64 and 65 of the Act, which deal with overtime working hours in factories, says the hours will be increased to 100 from the existing 50.

The proposals also seek to shift the blame for industrial accidents from the proprietor to the manager of a factory provided it is government-owned, by changing the definition of “occupier” of the factory in Section 2 (n) from the “person who has ultimate control over affairs of a factory” to the “person appointed to manage the factory”.

Workers who are working more hours of overtime are prone to making mistakes. There is a growing shortage of experienced qualified chemical plant operators in India and the proposed increase in overtime hours may affect process safety. The second proposed change of transferring accountability for Government owned companies to the person appointed to manage the factory may lead to a situation where the unit head in a government owned factory may resign when he or she finds things are not going his/her way with regard to process safety. This will lead to a discontinuity in managing process safety.

Read the article in this link.

March 16, 2011

Changes to my blog

Based on feedback from readers, I have added categories in my blog http://indiaprocesssafety.blogspot.com where u can browse the following postings:

Incidents (99)

Safe work practices (28)

BP Oil Rig Disaster (19)

Incident Investigation (19)

Organisational Culture (19)

Bhopal (17)

Emergency planning and response (15)

Mechanical integrity (15)

PSM (13)

Process design (10)

Human factors (9)

Audits (7)

Fire and explosion (7)

Runaway reactions (7)

Process safety and security (6)

Instrumentation (5)

Siting (5)

Transportation accidents (5)

LOPA (4)

Process Safety and Aviation (4)

Risk management (4)

Training (3)

Behaviour based safety (2)

Indian Regulatory (2)

Managing change (2)

Shutdown systems (2)

Vacuum hazards (2)

Alarm management (1)

Backup systems (1)

CSB Safety videos (1)

MSDS (1)

Incidents (99)

Safe work practices (28)

BP Oil Rig Disaster (19)

Incident Investigation (19)

Organisational Culture (19)

Bhopal (17)

Emergency planning and response (15)

Mechanical integrity (15)

PSM (13)

Process design (10)

Human factors (9)

Audits (7)

Fire and explosion (7)

Runaway reactions (7)

Process safety and security (6)

Instrumentation (5)

Siting (5)

Transportation accidents (5)

LOPA (4)

Process Safety and Aviation (4)

Risk management (4)

Training (3)

Behaviour based safety (2)

Indian Regulatory (2)

Managing change (2)

Shutdown systems (2)

Vacuum hazards (2)

Alarm management (1)

Backup systems (1)

CSB Safety videos (1)

MSDS (1)

Where there is a human, there will be an error!

A report in the Hindustan Times about the investigation of a fire in Air India flight on September 4,2009 points out the following:

"A probe by the aviation regulator has found several safety lapses by Air India staff while evacuating 213 passengers from a Mumbai-Riyadh flight after a fire broke out in the aircraft on September 4, 2009. The Directorate General of Civil Aviation (DGCA) concluded that the AI's aircraft maintenance engineer failed to notice a fuel leak from the left side of aircraft before clearing it for take-off. "The engineer had left the bay without giving the final take-off clearance because it was raining," the report said.

Second, the airline ground staff were unable to report the fire to the pilots because the cockpit crew had switched off the radio communication equipment, violating the airline's operation manual. Worse, both the pilots left the aircraft before the evacuation process was complete and not a single cabin crew member was deployed at the end of the inflated emergency slides to assist passengers.

The report also blamed the airline engineers for failing to check the aircraft's fuel channel during routine inspection. "Constant wear and tear caused massive fuel leakage and fire," said the report.

An airport follow-me vehicle informed the air traffic controller on duty about the fuel leak but he wasted significant time in alerting the pilots, the report stated. "As per rules, the controller should have called the aircraft crew by its registration number but it kept calling the flight number," read the report.

The cockpit crew switched off the aircraft engine but was late to start the evacuation process. The cabin crew also overlooked hand signals about the fire from the ground staff."

It always takes a series of human errors to trigger an incident. In the chemical industry also, a similar situation exists. Pressure on production, lack of rest, overloading of equipment, communication gaps and top management disconnects are often common cause reasons for incidents.

Read the news report in this link.

"A probe by the aviation regulator has found several safety lapses by Air India staff while evacuating 213 passengers from a Mumbai-Riyadh flight after a fire broke out in the aircraft on September 4, 2009. The Directorate General of Civil Aviation (DGCA) concluded that the AI's aircraft maintenance engineer failed to notice a fuel leak from the left side of aircraft before clearing it for take-off. "The engineer had left the bay without giving the final take-off clearance because it was raining," the report said.

Second, the airline ground staff were unable to report the fire to the pilots because the cockpit crew had switched off the radio communication equipment, violating the airline's operation manual. Worse, both the pilots left the aircraft before the evacuation process was complete and not a single cabin crew member was deployed at the end of the inflated emergency slides to assist passengers.

The report also blamed the airline engineers for failing to check the aircraft's fuel channel during routine inspection. "Constant wear and tear caused massive fuel leakage and fire," said the report.

An airport follow-me vehicle informed the air traffic controller on duty about the fuel leak but he wasted significant time in alerting the pilots, the report stated. "As per rules, the controller should have called the aircraft crew by its registration number but it kept calling the flight number," read the report.

The cockpit crew switched off the aircraft engine but was late to start the evacuation process. The cabin crew also overlooked hand signals about the fire from the ground staff."

It always takes a series of human errors to trigger an incident. In the chemical industry also, a similar situation exists. Pressure on production, lack of rest, overloading of equipment, communication gaps and top management disconnects are often common cause reasons for incidents.

Read the news report in this link.

March 15, 2011

Chemical Reactor Safety

The UK Health and Safety Executive has a write up on test methods for exothermicity for chemical reactors. Quoting from the article,

“The main types of test are:

1) basic screening tests;

2) isothermal calorimetry, aimed at quantifying reaction kinetics, heats of reaction, etc for particular reaction systems;

3) adiabatic calorimetry, used mainly for examining the runaway potential of reactions and individual compounds; and

4) combination instruments intended not only to give thermal data but also to calculate appropriate reactor vent sizes.

These tests tend not to give absolute results, in that the experimental conditions may affect the data obtained. Factors such as sample size, container material, heating rate, thermal inertia and endothermic effects (eg evaporation, gas evolution and phase changes) can all affect the result. The work, therefore, needs to be carried out by persons who are adequately trained and experienced in this type of investigation, to ensure that in each case suitable techniques are employed and adequate account is taken of experimental variables”.

Read the write up in this link.

Nuclear and process safety - Part 2

For those of who saw the videos of the explosion in the nuclear reactor in Japan, you must have observed the blast wave destroying the wall panels but the metal structure stayed intact. I believe the design worked as intended. But the news that sea water is being used for cooling indicates the seriousness of the situation. In a chemical plant emergency, we do not have to deal with radiation leaks but imagine the plight of the emergency responders in the Japan nuclear plant. They must wear protective clothing for the radiation and tackle the emergency also. For those of you who want to know a little more about the nuclear reactor incident, see this link

Another good article is in this link.

Read an explanation about the second reactor explosion in this link.

Another good article is in this link.

Read an explanation about the second reactor explosion in this link.

March 12, 2011

Earthquakes and nuclear /process safety

Our prayers are with the victims of the Japan earthquake. A BBC news article mentions the following:

"Japan's prime minister has declared a "nuclear emergency" after a number of reactors shut down in the wake of a massive earthquake hitting the country.Eleven reactors at four nuclear power stations automatically shut down, but officials said one reactor's cooling system failed to operate correctly.

Under Japanese law, an emergency must be declared if a cooling system fails.

In total, the country has 55 reactors providing about one-third of the nation's electricity.

In a statement, the Japan Atomic Industrial Forum released a statement that said Prime Minister Naoto Kan had declared the emergency "in case prompt action" had to be taken, but added that "no release of radioactive material" had been detected.

"Since emergency diesel generators at the Fukushima-1 and -2 NPPs are out of order, (energy company) TEPCO sent the emergency report to Nisa. There is no report that radiation was detected out of the site."

The reactor at the Fukushima Daiichi power station that triggered the emergency alert was the 40-year-old Reactor 1, one of six on the site.Reactors 1, 2 and 3 automatically shut down when the Magnitude 8.9 quake shook the plant, while reactors 4, 5 and 6 were not in operation as they were undergoing scheduled inspections.

It is understood that the earthquake cut electricity supplies to the power station, and the back-up generators did not come into operation when the outage occurred. As a result, not all of the cooling systems were available".

Obviously something happened to the back up generators and they could not come in line. We have to wait for the investigation report to come out.

Read the BBC article in this link.

Read an article about the seismic zoning in India in this link.

"Japan's prime minister has declared a "nuclear emergency" after a number of reactors shut down in the wake of a massive earthquake hitting the country.Eleven reactors at four nuclear power stations automatically shut down, but officials said one reactor's cooling system failed to operate correctly.

Under Japanese law, an emergency must be declared if a cooling system fails.

In total, the country has 55 reactors providing about one-third of the nation's electricity.

In a statement, the Japan Atomic Industrial Forum released a statement that said Prime Minister Naoto Kan had declared the emergency "in case prompt action" had to be taken, but added that "no release of radioactive material" had been detected.

"Since emergency diesel generators at the Fukushima-1 and -2 NPPs are out of order, (energy company) TEPCO sent the emergency report to Nisa. There is no report that radiation was detected out of the site."

The reactor at the Fukushima Daiichi power station that triggered the emergency alert was the 40-year-old Reactor 1, one of six on the site.Reactors 1, 2 and 3 automatically shut down when the Magnitude 8.9 quake shook the plant, while reactors 4, 5 and 6 were not in operation as they were undergoing scheduled inspections.

It is understood that the earthquake cut electricity supplies to the power station, and the back-up generators did not come into operation when the outage occurred. As a result, not all of the cooling systems were available".

Obviously something happened to the back up generators and they could not come in line. We have to wait for the investigation report to come out.

Read the BBC article in this link.

Read an article about the seismic zoning in India in this link.

March 11, 2011

Making Process Safety Management Work

I am quoting excerpts from a recent speech by Mr Bob Dudley (Group CEO, BP) that is on the BP website

“We have created a powerful, central safety and operational risk organization headed by Mark Bly, who led our internal investigation of the accident. Mark reports directly to me and sits on our executive team.

His organization has the resources and the mandate to drive safe, reliable, and compliant operations, including intervention rights, in BP’s exploration and production operations anywhere in the world.

The new organization is now in action across BP in four main areas:

First, it is strengthening and clarifying requirements for safe, compliant and reliable operations.

Second, it is deploying around 500 specialist personnel within our businesses to guide, advise, and if necessary, intervene.

Third, it is providing deep technical expertise to our operating businesses.

And fourth, it is intervening where needed to stop operations and bring about corrective actions.

We are already seeing results.

For example, we have shut in one production platform to repair the fire water pumps. Another platform was shut down after the discovery of incorrect specifications for some fasteners. And a producing field was shut down to enable pipeline integrity work to be carried out. Further, we have decided we will not take rigs that do not conform to our standards and there are a number of cases where we have either turned away rigs or are negotiating for modifications which could bring the rig up to our standards.

We are conducting a major review of our risk management systems to ensure we have consistent standards that are applied in a disciplined way across BP.

And in support of all of this, we are linking our performance management and reward system directly to safety and risk management - as well as to key behaviours – teamwork, capability-building, listening and compliance with standards.

We will focus on the critical inputs that drive delivery, namely safety, capability, technology and relationships, rather than focussing primarily on outputs such as production barrels. If we get these right, then the outputs, including dollars, will follow. So we are emphasizing quality over quantity and value over volume.

We also learned a lot about what crisis management means in a world of 24 hour communications with massive social media coverage as well as conventional press and cable broadcasting. I saw how much pressure there is on everyone to take up polarized positions and over-simplify the issues”.

The above points mentioned by the CEO has tremendous significance on Process Safety. I am postulating some simple rules if you want process safety to work:

1. You must be prepared to walk the talk if you want process safety to succeed.

2. Technical expertise is the key to maintaining process safety. Just having standards and a system is not enough. You must have technically competent people who understand the implications of the standards.

3. The board of directors must have direct access to technically competent people who can translate risks and their implications to them.

4.Your organizational framework must institutionalize process safety management

5. If process safety is taken care of, profits will automatically follow. This lesson is most important for the people who control the purse strings!

Read the complete speech in this link.

Subscribe to:

Posts (Atom)