What is a blowout preventer? In the Deepwater Horizon oil rig disaster, it is suspected that the blowout preventer failed. Please see Wikepedia's explanation given below:

BOPs come in a variety of styles, sizes and pressure ratings, and usually several individual units comprise a BOP stack. Blind rams are designed to close an open wellbore. Pipe rams seal around tubular components in the well (drill pipe, casing, tubing, or coiled tubing). Shear-seal BOPs are fitted with hardened steel shearing surfaces that can actually cut through drill pipe and tool strings, if all other barriers fail. Since BOPs are important for the safety of the crew, as well as the drilling rig and the wellbore itself, BOPs are regularly inspected, tested and refurbished. Tests vary from daily test of functions of critical wells to monthly or less frequent testing of wells with low likelihood of control problems.Any of these BOPs may be installed underwater, normally with two hydraulic actuators.

Deepwater Horizon blowout

After the Deepwater Horizon drilling rig explosion on April 20, 2010, the blowout preventer should have activated itself automatically to avoid an oil spill in the Gulf of Mexico. Underwater robots were sent to manually activate the mechanism's switch, to no avail. As of May 2010[update] it is unknown why it failed.BP representatives suggested that the preventer could have suffered a hydraulic leak. Gamma-ray imaging of the preventer conducted on May 12 and May 13, 2010 showed that the preventer's internal valves were partially closed and were restricting the flow of oil. Whether the valves closed automatically during the explosion or were shut manually by ROV is unknown.

Please see this link for a pdf version powerpoint presentation of BOP (large file-be patient!).

May 24, 2010

Organisational culture and Process Safety

I always keep wondering why companies spend so much money on implementing behaviour based safety systems when in real life, what is actually required is the behaviour of top management towards process safety! If top management are able to track and recognize the process safety issues that need attending to, then the organizational culture will be conducive for the success of PSM. A walk around by top management to every nook and corner of their plant once in 6 months is adequate for them to understand the PSM issues!Organizational safety culture must come from the top and it is free to implement!

A recent OSHA report mentions the following:

Since the BP Texas City explosion in 2005, OSHA has counted over 20 serious incidents in refineries across the country.

Last year, OSHA completed an investigation of a naphtha piping failure and release, in which the resulting explosion and fire seriously injured three workers; two other workers, relatively young at 49 and 53 years old, died. One of these two workers was killed in the explosion; the other struggled for 13 days in the hospital before dying from severe burns. Within the unit where this rupture occurred, OSHA discovered multiple pipes that were operating below their retirement wall thickness. In fact, the very line that ruptured had previously ruptured and had to be replaced a decade earlier. As this tragedy makes clear, this type of breakdown maintenance is simply unacceptable. Good mechanical integrity programs are absolutely essential to safe refinery operation.

In 2007, water freezing in liquid propane piping resulted in a jet fire and a rapid evacuation of the entire refinery. Three workers, aged 33, 35, and 42 were seriously burned and hospitalized. Investigators found that a Process Hazard Analysis team had recommended installing remotely operable shut-off valves, yet the recommendation was improperly closed as "complete" by the previous owner. In fact, the valves had not been installed at all. The lack of these shut-off valves impeded workers' ability to control the propane release before it ignited. The refinery learned a hard lesson: It is essential to rigorously follow up on PHA findings to ensure that hazards are adequately controlled. Failure to abate serious hazards can have deadly consequences.

In 2008, at another facility, an explosion in a hydrocracking unit blew the head off a process water filter. The debris struck and killed a foreman; he was 53 and had been with the company for 30 years. OSHA's investigation revealed that an inadequate start-up procedure had allowed hydrogen gas and air to accumulate in the top of the filter where it was likely ignited by pyrophoric deposits. OSHA learned that some operators had recognized the hazard and used an undocumented alternate approach that was actually safer, but the procedure had never been updated to incorporate the safer practice. The result of following the faulty procedure was a violent explosion and the needless death of a refinery worker ? and a reminder that having safe, complete, and accurate operating procedures is essential to safe operations in process units.

A recent OSHA report mentions the following:

Since the BP Texas City explosion in 2005, OSHA has counted over 20 serious incidents in refineries across the country.

Last year, OSHA completed an investigation of a naphtha piping failure and release, in which the resulting explosion and fire seriously injured three workers; two other workers, relatively young at 49 and 53 years old, died. One of these two workers was killed in the explosion; the other struggled for 13 days in the hospital before dying from severe burns. Within the unit where this rupture occurred, OSHA discovered multiple pipes that were operating below their retirement wall thickness. In fact, the very line that ruptured had previously ruptured and had to be replaced a decade earlier. As this tragedy makes clear, this type of breakdown maintenance is simply unacceptable. Good mechanical integrity programs are absolutely essential to safe refinery operation.

In 2007, water freezing in liquid propane piping resulted in a jet fire and a rapid evacuation of the entire refinery. Three workers, aged 33, 35, and 42 were seriously burned and hospitalized. Investigators found that a Process Hazard Analysis team had recommended installing remotely operable shut-off valves, yet the recommendation was improperly closed as "complete" by the previous owner. In fact, the valves had not been installed at all. The lack of these shut-off valves impeded workers' ability to control the propane release before it ignited. The refinery learned a hard lesson: It is essential to rigorously follow up on PHA findings to ensure that hazards are adequately controlled. Failure to abate serious hazards can have deadly consequences.

In 2008, at another facility, an explosion in a hydrocracking unit blew the head off a process water filter. The debris struck and killed a foreman; he was 53 and had been with the company for 30 years. OSHA's investigation revealed that an inadequate start-up procedure had allowed hydrogen gas and air to accumulate in the top of the filter where it was likely ignited by pyrophoric deposits. OSHA learned that some operators had recognized the hazard and used an undocumented alternate approach that was actually safer, but the procedure had never been updated to incorporate the safer practice. The result of following the faulty procedure was a violent explosion and the needless death of a refinery worker ? and a reminder that having safe, complete, and accurate operating procedures is essential to safe operations in process units.

May 22, 2010

Facility siting and hazardous chemicals

Greenpeace has sent a blimp over a chemical plant in Delaware, as part of a worldwide campaign to eliminate toxic chemicals. Their focus is on toxic chemicals that could spread in an airborne plume if released suddenly by an accident or terrorist attack. The article mentions that "Federal risk management reports indicate that up to 660,000 people live in potential “downwind” areas at risk in the event of a sudden, complete release from one of the 90-ton chlorine tank cars routinely parked at Edge Moor in east Wilmington.A similar accident at the Chambers Works operation, near the Delaware Memorial Bridge, could endanger 2 million people, by federal estimates".

In India, the problem is more acute.Residential dwellings are allowed to come up in the no man zone surrounding hazardous chemical factories.

Read the full article in this link

In India, the problem is more acute.Residential dwellings are allowed to come up in the no man zone surrounding hazardous chemical factories.

Read the full article in this link

May 21, 2010

Cyclone Laila and Headcount procedures

Today's Times of India carries an article mentioning that cyclone Laila uprooted one of the anchors of the ONGC oil rig Sagar Vijay in the Bay of Bengal, thus destabilising the rig. The article also mentions that ONGC could not give the exact number of people on board at the time of the incident.How robust are your headcount procedures? Test them in surprise tests. During mock drills everything is hunky dory but when an emergency strikes, are your systems telling you the exact number of personnel inside your facility? A proper head count system prevents body counts.

When I worked in the Middle East, I was also a volunteer firefighter for the plant firefighting team. We had an elaborate head count system for firefighters also, to ensure that all firefighters are accounted for. It is better to plan for the worst.It does not cost much but can save lives!

When I worked in the Middle East, I was also a volunteer firefighter for the plant firefighting team. We had an elaborate head count system for firefighters also, to ensure that all firefighters are accounted for. It is better to plan for the worst.It does not cost much but can save lives!

Dust explosions and vacuum cleaners

The CSB has been doing a great service by increasing awareness about dust explosions. Dust explosions can occur in sugar, sawdust, coal, and in fact anything that is combustible including combustible metals. Housekeeping plays a very important part in eliminating dust in the work area. Industrial vacuum cleaners are available to do the job safely. One such cleaner is given in this youtube link. I am not endorsing their product but I thought that the video was a good one!

Hydrogen incidents

Click here for the site. This site is a useful site for incidents connected with hydrogen. For those of you dealing with this dangerous gas, these incidents will help you understand its dangers. Hydrogen is handled in refineries,ammonia plants and chlor alkali industries.

May 20, 2010

Blowing of natural gas lines

Finally the CSB has released a statement about natural gas blowing of pipelines. A survey has been conducted by CSB. "According to the survey, using natural gas to clean pipes remains the most common single practice in industry, employed by 37% of respondents. The other respondents reported using nitrogen, which is nonflammable, or inherently safer alternatives such as air, steam, or cleaning pigs. On February 25, 2010, eighteen days after the explosion at Kleen Energy, the CSB stated that natural gas blows were “inherently unsafe” and urged industry to seek alternatives".

Even last week, I had warned a natural gas user to prevent the blowing of lines with natural gas itself instead of using nitrogen. Read more of the CSB statement in this link.

Read my earlier post on the topic in this link.

Even last week, I had warned a natural gas user to prevent the blowing of lines with natural gas itself instead of using nitrogen. Read more of the CSB statement in this link.

Read my earlier post on the topic in this link.

May 19, 2010

Confined spaces are deadly

Time and again, we realize how deadly a confined space can be but lives continue to be lost. The number of deaths we have read in newspapers involving conservancy workers entering sewers and asphyxiated by hydrogen sulfide are countless. In chemical plants,refineries,food industry, transportation industry, power generation, pulp, paper and other industries, deadly gases can accumulate inside confined spaces. No wonder they are called silent killers. CO, H2S, CO2,CH4, Ammonia, paint,thinners, solvents, nitrogen are all deadly inside a confined space. Reactions that take place inside confined spaces including fermentation can make the confined spaces deadly.

Treat your confined spaces with respect. Have a proper confined space entry permit that is enforced.Read some of the accidents in confined spaces in this link

The CSB video on hazards of nitrogen in confined spaces can be viewed in this link.

Read an interesting article on confined space threats to farmers in this link!

Treat your confined spaces with respect. Have a proper confined space entry permit that is enforced.Read some of the accidents in confined spaces in this link

The CSB video on hazards of nitrogen in confined spaces can be viewed in this link.

Read an interesting article on confined space threats to farmers in this link!

May 17, 2010

Oleum release incident - CSB findings

The CSB has released its final report on the uncontrolled oleum release from INDSPEC Chemical Corporation in Petrolia, Pennsylvania, which forced the evacuation of three surrounding towns in October 2008.Oleum was released when a tank transfer operation was left unattended during weekend operations and an oleum storage tank overflowed.

The CSB investigation has determined that the normal power supply for the three oleum transfer pumps was equipped with a safety interlock, which would automatically shut off the flow of oleum when the receiving tank was full, thus preventing a dangerous overflow. However, the oleum storage building also had an auxiliary or 'emergency' power supply that had been installed in the late 1970s. It was originally intended as a temporary measure to keep the pumps functioning during interruptions of the normal power supply but eventually the emergency power supply became a permanent fixture. Facility management never installed interlocks for the emergency power and written operating procedures did not address how or when the emergency power supply should be used.

The CSB case study report identifies four key safety lessons for companies:

- In the 1980s, the facility changed the structure of the emergency power supply from temporary wiring to permanent conduit. The facility did not evaluate the significance of this change.

- The facility installed the emergency power supply without the engineering controls that already existed on the normal power supply.

-The facility's storage system design required operators to transfer oleum on the weekend to ensure operations were unaffected during the week. Operators used a work practice developed years earlier to transfer oleum using two pumps concurrently. This work practice was never recorded in written operating procedures.Management must remain vigilant in evaluating how work is actually performed.

- The facility never included information on the emergency power supply in piping and instrumentation diagrams and written operating procedures. Personnel hazard assessment (PHA) teams were therefore unable to evaluate the consequences of emergency power supply use.

Read the report in this link

The CSB investigation has determined that the normal power supply for the three oleum transfer pumps was equipped with a safety interlock, which would automatically shut off the flow of oleum when the receiving tank was full, thus preventing a dangerous overflow. However, the oleum storage building also had an auxiliary or 'emergency' power supply that had been installed in the late 1970s. It was originally intended as a temporary measure to keep the pumps functioning during interruptions of the normal power supply but eventually the emergency power supply became a permanent fixture. Facility management never installed interlocks for the emergency power and written operating procedures did not address how or when the emergency power supply should be used.

The CSB case study report identifies four key safety lessons for companies:

- In the 1980s, the facility changed the structure of the emergency power supply from temporary wiring to permanent conduit. The facility did not evaluate the significance of this change.

- The facility installed the emergency power supply without the engineering controls that already existed on the normal power supply.

-The facility's storage system design required operators to transfer oleum on the weekend to ensure operations were unaffected during the week. Operators used a work practice developed years earlier to transfer oleum using two pumps concurrently. This work practice was never recorded in written operating procedures.Management must remain vigilant in evaluating how work is actually performed.

- The facility never included information on the emergency power supply in piping and instrumentation diagrams and written operating procedures. Personnel hazard assessment (PHA) teams were therefore unable to evaluate the consequences of emergency power supply use.

Read the report in this link

Importance of Near misses in process safety

A newspaper report (Hindu dated 14.5.10) indicates the following points about the oil spil in the Gulf of Mexico:"Oil executives ignored warning signs in the hours before the Deepwater rig explosion in the Gulf of Mexico last month, a congressional hearing heard on Wednesday.

In a second day of hearings, the U.S. House of Representatives' energy and commerce committee said documents and briefings suggested that BP, which owned the well; Transocean, which owned the rig; and Halliburton, which made the cement casing for the well, ignored tests in the hours before the 20 April explosion that indicated faulty safety equipment".

No major incident occurs without warning. Do not ignore your near misses!Read more of the article in this link

In a second day of hearings, the U.S. House of Representatives' energy and commerce committee said documents and briefings suggested that BP, which owned the well; Transocean, which owned the rig; and Halliburton, which made the cement casing for the well, ignored tests in the hours before the 20 April explosion that indicated faulty safety equipment".

No major incident occurs without warning. Do not ignore your near misses!Read more of the article in this link

Bhopal Gas disaster and the recent BP oil spill

A newspaper report indicates that the verdict on the Bhopal Gas Disaster court case will be delivered on June 7th,2010 in a Bhopal Court in India. During the trial, 178 prosecution witnesses and 3008 documents were examined. The disaster happened in 1984 and the wheels of Justice move slowly! Cut to the recent BP oil spill in the Gulf of Mexico last month. Already the US house of representatives has begun an inquiry to pinpoint responsibility and accountability. In the Bhopal gas disaster, the entire liability was settled for 470 million US dollars. In 1989 a oil tanker called Exxon Valdez spilled oil in Alaska and the damages reportedly paid by Exxon was US dollar 5 billion. Exxon reportedly paid US dollar 940 each for every penguin that was contaminated with oil and had to be cleaned. In contrast, the Bhopal gas victims damaged for life received US Dollar 500 each!(Source: Greenpeace report).

Lets us wait for the verdict in the Bhopal Gas Disaster!!

Lets us wait for the verdict in the Bhopal Gas Disaster!!

May 10, 2010

Crisis management and the media

The BP oil spill and the media coverage about it throws up the powerful role of the internet in disseminating information. Companies must be fully prepared to handle such crisis. BP is also using twitter to keep the public updated on the oil spill containment efforts. In India, most of the the media coverage of any incident borders on the paranoid and is aimed at getting high viewership ratings at that instant. The Jaipur oil depot fire is a classic example of this. Companies must have a crisis management plan ready and test it periodically.

May 9, 2010

Process Safety and Leadership

After the BP Texas disaster in 2005, the then CEO of BP Lord John Browne resigned and Mr Tony Hayward took over. An article mentions the following: 'When Mr. Hayward took over BP's leadership from John Browne three years ago this week, the company was at one of the lowest points in its history: badly run, accident-prone and accused in the aftermath of a deadly explosion at its Texas City refinery of putting profits before safety. Mr. Hayward turned BP around, boosting production, cutting costs and significantly reducing on-the-job injuries. Mr.Hayward set about radically simplifying the company and cutting costs. Senior executives were cut by a quarter. In all, 6,500 people, or just under 10% of its work force, lost their jobs. Last month, he was confident enough to talk of an irreversible "change of culture" at BP.None of that seems to matter now, as BP heads into the crisis grinder that has chewed up big names like Toyota and Goldman Sachs. And with about 5,000 barrels of oil leaking from the damaged well each day, Mr. Hayward knows it".

Read more about this interesting article in this link.

Read about the mitigation efforts in this link

Read more about this interesting article in this link.

Read about the mitigation efforts in this link

Process safety information and BP incident

A number of articles are going around on the BP oil spill incident. In one of them, a whistleblower is supposed to have raised safety concerns about BP Atlantis, the world’s largest and deepest semi-submersible oil and natural gas platform. In this article it mentions the following "It was then that the whistle-blower, who was hired to oversee the company’s databases that housed documents related to its Atlantis project, discovered that the drilling platform had been operating without a majority of the engineer-approved documents it needed to run safely, leaving the platform vulnerable to a catastrophic disaster that would far surpass the massive oil spill that began last week following a deadly explosion on a BP-operated drilling rig.

BP’s own internal communications show that company officials were made aware of the issue and feared that the document shortfalls related to Atlantis “could lead to catastrophic operator error” and must be addressed.“The risk in turning over drawings that are not complete are: 1) The Operator will assume the drawings are accurate and up to date,” the email said. “This could lead to catastrophic Operator errors due to their assuming the drawing is correct,” said Duff’s email to BP officials Bill Naseman and William Broman. “Turning over incomplete drawings to the Operator for their use is a fundamental violation of basic Document control, [internal standards] and Process Safety Regulations.” Read more of this article in this link.

BP’s own internal communications show that company officials were made aware of the issue and feared that the document shortfalls related to Atlantis “could lead to catastrophic operator error” and must be addressed.“The risk in turning over drawings that are not complete are: 1) The Operator will assume the drawings are accurate and up to date,” the email said. “This could lead to catastrophic Operator errors due to their assuming the drawing is correct,” said Duff’s email to BP officials Bill Naseman and William Broman. “Turning over incomplete drawings to the Operator for their use is a fundamental violation of basic Document control, [internal standards] and Process Safety Regulations.” Read more of this article in this link.

May 2, 2010

BP Oil Spill

The latest BP oil spill in the Gulf of Mexico could turn out to be bigger than the Exxon Valdez spill. The President of the US himself has flown to Louisana for a first hand look. One would have thought that after the BP Texas Disaster in 2005, many checks and balances would have been put to prevent another disaster. We will have to wait and see the results of the investigation...

See photos of the spill in this link

See photos of the spill in this link

May 1, 2010

Process safety in batch operations

What goes around comes around! As far as process safety incidents in batch process go, I sometimes despair whether we will ever learn from previous incidents. Last year I had investigated some batch process incidents, the causes of which are very very familiar - incompatibility,scale up issues, heat removal issues, MSDS issues and raw material storage issues. For those of you working in the batch process industry, the UK Chemical Reaction Hazards Forum is a good place to get information on batch incidents. Share these incidents with your operating personnel and check whether it could happen in your organization. For further details go to this link.

What I learnt in Process Safety – A tribute to my senior managers at Madras Fertilizers Ltd

32 years ago, I joined the ammonia plant in Madras Fertilizers as a graduate engineer trainee and then went on to be shift in charge and assistant manager in the ammonia plant. The lessons I learnt in process safety from the senior management* are still fresh in my mind. There was no PSM system, no ISO 14001, no OHSAS 18001, but in the ten years I was there, there was no serious process safety incident!

The senior management then were all experts in plant operation and maintenance – you could not fool them! Their decisions were taken appropriate to the risk involved and clearly communicated. They also made sure that critical jobs which had a process safety issue were always supervised by them by giving clear instructions and follow up. This way we knew when we were going off track and correct ourselves before anything happened. They were true “managers” – who played the fine line between process safety and production with such a finesse, you could not but admire and learn from them.

We did take a lot of “process safety risks” when there was a situation, but it was a calculated and clearly communicated risk – with the result, we were always under control.

Cut to today – Today in many plants, there are distinct gaps between what senior management think what is going on as far as process safety is concerned and what is actually happening at the ground level. Why is this happening? My own understanding of the situation leads to the following:

1.Some of the senior management do not have an understanding of the plant – they may be qualified MBA’s but in a chemical plant, what matters most at senior management level is their conceptualization of key process safety risks!

2.Many Senior management do not want to hear “bad news” related to process safety but welcome “bad news” related to sales and profits. I compare the senior management I started my career with many of the senior management today – the difference is that “bad news related to process safety” used to be ferreted out by the senior management I worked with, even though I may think it was not necessary to tell them!

3.Many boards of directors in present chemical companies do not have a clear understanding of the difference between process safety and occupational health and safety.

4.Senior management are led astray by the numerous certifications of ISO 14001/OHSAS18001 etc. leading to a false sense of complacency.

5.Many of the reactions of management today after a process safety incident are of a knee jerk reaction. A comprehensive long term approach is lacking. Everyone wants to safeguard their remaining time with the organization!

*I pay a strong tribute to my former senior managers at MFL: (Late) Mr P.N.Arunachalam, Mr Jacob Eapen, Mr N.Gajendran and (Late) Mr S.Rangaiah

The senior management then were all experts in plant operation and maintenance – you could not fool them! Their decisions were taken appropriate to the risk involved and clearly communicated. They also made sure that critical jobs which had a process safety issue were always supervised by them by giving clear instructions and follow up. This way we knew when we were going off track and correct ourselves before anything happened. They were true “managers” – who played the fine line between process safety and production with such a finesse, you could not but admire and learn from them.

We did take a lot of “process safety risks” when there was a situation, but it was a calculated and clearly communicated risk – with the result, we were always under control.

Cut to today – Today in many plants, there are distinct gaps between what senior management think what is going on as far as process safety is concerned and what is actually happening at the ground level. Why is this happening? My own understanding of the situation leads to the following:

1.Some of the senior management do not have an understanding of the plant – they may be qualified MBA’s but in a chemical plant, what matters most at senior management level is their conceptualization of key process safety risks!

2.Many Senior management do not want to hear “bad news” related to process safety but welcome “bad news” related to sales and profits. I compare the senior management I started my career with many of the senior management today – the difference is that “bad news related to process safety” used to be ferreted out by the senior management I worked with, even though I may think it was not necessary to tell them!

3.Many boards of directors in present chemical companies do not have a clear understanding of the difference between process safety and occupational health and safety.

4.Senior management are led astray by the numerous certifications of ISO 14001/OHSAS18001 etc. leading to a false sense of complacency.

5.Many of the reactions of management today after a process safety incident are of a knee jerk reaction. A comprehensive long term approach is lacking. Everyone wants to safeguard their remaining time with the organization!

*I pay a strong tribute to my former senior managers at MFL: (Late) Mr P.N.Arunachalam, Mr Jacob Eapen, Mr N.Gajendran and (Late) Mr S.Rangaiah

April 30, 2010

Process safety and security

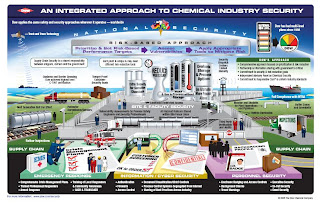

Dow Chemicals has beautifully pictured their "integrated approach to chemical security management" on their website in this link

I wonder when India will really wake up to chemical security threats and bring in legislation and enforce it. With the threats of naxalites and external terrorists and the fact that a number of hazardous chemical units are based on the coast,it becomes imperative that a coordinated approach to chemical plant security is implemented. Let us not wait for an attack to happen!

Fire at Pharma Plant at Ankleshwar

An article in economic times mentions the following "A fire at pharmaceutical major Wockhardt’s Rs 300-crore Ankleshwar facility damaged one of its six manufacturing plants. It will take six months to recommission the unit, a company spokesman said.

The incident adds to the woes of a debt-laden Wockhardt, which had defaulted on payment of its overseas convertible bonds last year, and was forced to accept a corporate debt restructuring package that included sale of some company assets". Read the full article at this link.

While the cause is being investigated, it must be remembered that when companies go under loss, it requires a great effort to maintain safety systems.

The incident adds to the woes of a debt-laden Wockhardt, which had defaulted on payment of its overseas convertible bonds last year, and was forced to accept a corporate debt restructuring package that included sale of some company assets". Read the full article at this link.

While the cause is being investigated, it must be remembered that when companies go under loss, it requires a great effort to maintain safety systems.

April 29, 2010

Process safety - uncomplicate things!

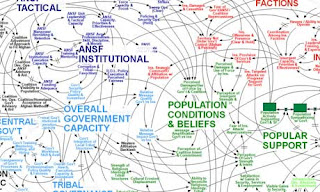

In the Times of India April 28,2010, an article mentions that powerpoint is the US military's new enemy - A general is reported to have said "When we understand that slide (seen above), we would have won the war"! The same general has said that "Its dangerous because it can create the illusion of understanding and the illusion of control". Now what does this have to do with process safety? It is the same as the complicated powerpoint! Just because you perform a complex PHA, SIL study or conduct a management of change study does not mean everything is in control. I have seen many incidents occur even though such studies were conducted. Be practical while conducting these studies and do not go overboard!

April 28, 2010

Process Safety and Overflow protection

I read a nice article on high integrity overflow protection. In the article there is a statement that one of the key requirements of a high integrity overfill protection self certification program is "Acknowledged competency to review the design aspects of both mechanical- and/or electrical-components including component failure modes, fail-safe vs. fail-danger, any claimed automatic diagnostics, and internal redundancy in order to produce a quantitative failure rate (This number will eventually plug into calculations that determine if a particular design meets its defined SIL requirements".

I have observed many SIL (Safety Integrity Level) studies where the above competency becomes suspect. Many organisations think that just because they have completed a SIL study, they are safe. A SIL study starts from a good PHA (Process Hazard Analysis) study and here itself, if the competency of the people participating in the study is inadequate, then "garbage in, garbage out".

In many cases, there has been an overkill of recommendations from a SIL study, leading to the organization spending money unnecessarily.

Read more of the article in this link

I have observed many SIL (Safety Integrity Level) studies where the above competency becomes suspect. Many organisations think that just because they have completed a SIL study, they are safe. A SIL study starts from a good PHA (Process Hazard Analysis) study and here itself, if the competency of the people participating in the study is inadequate, then "garbage in, garbage out".

In many cases, there has been an overkill of recommendations from a SIL study, leading to the organization spending money unnecessarily.

Read more of the article in this link

Process Safety in LPG storage

At Vishakapatnam, the storage of LPG is being done in underground caverns as well as mounded storage. The underground storage facility is an engineering feat by itself.

"A safe method for the storage of large quantities of LPG is Cavern storage. In this method, LPG is stored in mined/artificial caverns at a depth of 160 m to 200 m below the sea level. Cavern is subjected to an external pressure by the saturated rock around the surface, which facilitates in the containment of LPG. The cavern storage is economical only for storage capacities above 50,000 mt and is feasible subject to the suitability of the rock, proximity to the ports with infrastructure for LPG receipt".

A nice description of the cavern is given by the company in this link.

For a draft paper on its construction and other details, please see this link.

HPCL, Visak has also constructed mounded storage of LPG. An article mentions that "Mounded storage of LPG i.e. creating a sand mound around the LPG storage vessels, which are placed above the ground level, is now increasingly being considered by HPCL as the best solution for protecting LPG vessels from BLEVE.

The mounded storage system provides the following advantages:

LPG stored in the form of mounded storage totally eliminates the possibility of BLEVE. The sand cover of 1 metre, which provides natural insulation from external heating, is adequate to outlast any fire in the surrounding areas. Water cooling systems are not required.

In addition, the mounding material provides good protection against most of the external influences like flying objects and pressure waves from explosions".

Read more of the article in this link

"A safe method for the storage of large quantities of LPG is Cavern storage. In this method, LPG is stored in mined/artificial caverns at a depth of 160 m to 200 m below the sea level. Cavern is subjected to an external pressure by the saturated rock around the surface, which facilitates in the containment of LPG. The cavern storage is economical only for storage capacities above 50,000 mt and is feasible subject to the suitability of the rock, proximity to the ports with infrastructure for LPG receipt".

A nice description of the cavern is given by the company in this link.

For a draft paper on its construction and other details, please see this link.

HPCL, Visak has also constructed mounded storage of LPG. An article mentions that "Mounded storage of LPG i.e. creating a sand mound around the LPG storage vessels, which are placed above the ground level, is now increasingly being considered by HPCL as the best solution for protecting LPG vessels from BLEVE.

The mounded storage system provides the following advantages:

LPG stored in the form of mounded storage totally eliminates the possibility of BLEVE. The sand cover of 1 metre, which provides natural insulation from external heating, is adequate to outlast any fire in the surrounding areas. Water cooling systems are not required.

In addition, the mounding material provides good protection against most of the external influences like flying objects and pressure waves from explosions".

Read more of the article in this link

April 26, 2010

Process Safety Information

I was reading an article where it mentions that a company in the USA was penalized for not having proper process safety information. Specifically the article mentions the following:

"The piping system was not provided with labels to indicate the contents or direction of flow. The proposed penalty is $5,600.

• The process safety information pertaining to the equipment in the process did not include the piping and instrument diagrams. The proposed penalty is $5,600.

• The process hazard analysis did not address the hazards of the process. The proposed penalty is $5,600.

• The standard operating procedures for the anhydrous ammonia rail car offloading rack did not address how the operator was to inspect the coupling or ensure that the coupling was serviceable. The proposed penalty is $5,600.

• The employer did not establish and implement written procedures to maintain the ongoing mechanical integrity of process equipment. The proposed penalty is $5,600.

• The ammonia offloading rack, including the coupling on the liquid ammonia offloading arm, had threads that were worn, resulting in the coupling coming apart, releasing more than 8,000 pounds of ammonia.

• The alarm system for evacuation voice alert was unintelligible in all locations within buildings on the plant site. The proposed penalty is $2,400".

Read the complete article in this link.

"The piping system was not provided with labels to indicate the contents or direction of flow. The proposed penalty is $5,600.

• The process safety information pertaining to the equipment in the process did not include the piping and instrument diagrams. The proposed penalty is $5,600.

• The process hazard analysis did not address the hazards of the process. The proposed penalty is $5,600.

• The standard operating procedures for the anhydrous ammonia rail car offloading rack did not address how the operator was to inspect the coupling or ensure that the coupling was serviceable. The proposed penalty is $5,600.

• The employer did not establish and implement written procedures to maintain the ongoing mechanical integrity of process equipment. The proposed penalty is $5,600.

• The ammonia offloading rack, including the coupling on the liquid ammonia offloading arm, had threads that were worn, resulting in the coupling coming apart, releasing more than 8,000 pounds of ammonia.

• The alarm system for evacuation voice alert was unintelligible in all locations within buildings on the plant site. The proposed penalty is $2,400".

Read the complete article in this link.

April 22, 2010

Process Safety - Effects of a Natural gas line rupture

Belgium's worst ever industrial disaster occurred on on July 30, 2004. At about 8:30am local time, people felt a strong smell of gas. The gas was leaking from an underground natural gas pipeline. Emergency responders arrived and were clearing the area when the gas caught fire and exploded. The official death toll was reported as 24. Please see graphic descriptions of the incident and its effects in this link.

Process Safety - oil rig explosion

An explosion has been reported at an oil rig contracted by BP. It appears that the CSB is considering investigating this incident. Please read full article in this link.

April 18, 2010

Process Safety and the Union's view

I read an interesting article about Process Safety and behaviour based safety and the unions perspective on it.In India, behaviour based safety is being bandied about by many as the ultimate solutions to all problems. Organisations have to understand that not only is the worker's behaviour responsible, it is also the behaviour of the top management that is also responsible for process safety!

Read the full article by the Steelworkers union in this link

Read the full article by the Steelworkers union in this link

April 10, 2010

Process Safety and Albert Einstein!

I read an interesting quote by Albert Einstein - " Only two things are infinite - the universe and human stupidity. And I am not so sure about the former."

Now how does this apply to Process Safety? Time and again, we see human errors and human factors being the root cause of incidents! The incidents I investigate tell me that Einstein is laughing in his grave! Will we ever learn from our past mistakes?

Lets wait and keep our fingers crossed.

Now how does this apply to Process Safety? Time and again, we see human errors and human factors being the root cause of incidents! The incidents I investigate tell me that Einstein is laughing in his grave! Will we ever learn from our past mistakes?

Lets wait and keep our fingers crossed.

Process Safety - Fire at Ankleshwar plant

A fire occurred at a pharma company in Ankleshwar. "The blaze at pharmaceutical major Wockhardt Ltd’s factory in Ankleshwar on Saturday was brought under control today. Additional fire tenders had to be called in from Vadodara, Ahmedabad and Surat and kept on standby.

“The fire was almost brought under control last night, but due to leakage of certain chemicals, there was re-ignition in some parts of the factory. The fire was completely extinguished by Sunday evening,” said Manoj Kutariya, Manager, Fire Safety, Disaster Prevention and Management Centre. . Read more in this link.

Just last month, there was a fire in another unit at Ankleshwar. I had visited the Disaster Prevention and Management Center about 6 months back and I was very impressed with the facilities and the team headed by Mr Manoj. Kudos to them.

“The fire was almost brought under control last night, but due to leakage of certain chemicals, there was re-ignition in some parts of the factory. The fire was completely extinguished by Sunday evening,” said Manoj Kutariya, Manager, Fire Safety, Disaster Prevention and Management Centre. . Read more in this link.

Just last month, there was a fire in another unit at Ankleshwar. I had visited the Disaster Prevention and Management Center about 6 months back and I was very impressed with the facilities and the team headed by Mr Manoj. Kudos to them.

Process Safety - OSHA penalises plastics plant

OSHA has penalized a plastics plant for deficiencies. The article says "The violations include the company's failure to properly contain polyvinyl chloride dust particles; evaluate contractors' safety programs and procedures; properly inspect process equipment; provide fire retardant clothing for employees; require employees to wear adequate eye protection with side shields; provide proper training; and provide employees with an infirmary, clinic, or person trained in first aid. Additionally, inspectors identified hazards involving a lack of machine guarding; a deficient process safety management program; inadequate lockout/tagout procedures for energy sources; and unguarded machinery, floor holes, and walkways. OSHA issues a serious citation when there is substantial probability that death or serious physical harm could result and the employer knew, or should have known, of the hazard".

It is interesting to note that the investigation was launched on the basis of a complaint of an employee! Read the full article in this link.

It is interesting to note that the investigation was launched on the basis of a complaint of an employee! Read the full article in this link.

April 4, 2010

Process Safety - Another day, another blast!

On Good Friday, another blast occurred in a refinery in the USA. The CSB will be investigating the incident but it appears that the CSB is now having its hands full with its investigators currently investigating other incidents. If this is the trend in the USA where PSM is mandatory, we must be very careful in India!

"A Washington state oil refinery hit by a deadly blast and fire early Friday was recently fined for safety violations amid what federal watchdogs call a troubling trend of serious accidents at refineries.

Three men died at the scene and two women died later at a Seattle hospital. Two other men were hospitalized with major burns over the majority of their bodies. It was the largest fatal refinery accident since a 2005 explosion at a BP American refinery in Texas killed 15 people and injured another 170.The Good Friday holiday blast rattled windows more than a mile away and has the most recorded fatalities since 15 workers were killed in a BP Plc incident in 2005 at that company’s Texas City, Texas, operations.

The Tesoro incident occurred as members of a seven-person crew were cleaning a heat exchanger in a unit handling naphtha, a volatile liquid chemically similar to jet fuel, Westfall told reporters.

The blast shook houses and woke people miles away, shooting flames as high as the refinery’s tower before the blaze was extinguished about 90 minutes later.

The blast occurred in a unit that was in the dangerous process of returning to operation, turning up heat and pressure, said Tesoro spokesman Greg Wright".

CSB Chairman and CEO John Bresland said, “The CSB has eighteen ongoing investigations. Of those, seven of these accidents occurred at refineries across the country. This is a significant and disturbing trend that the refining industry needs to address immediately.”

Read the complete article in this link

"A Washington state oil refinery hit by a deadly blast and fire early Friday was recently fined for safety violations amid what federal watchdogs call a troubling trend of serious accidents at refineries.

Three men died at the scene and two women died later at a Seattle hospital. Two other men were hospitalized with major burns over the majority of their bodies. It was the largest fatal refinery accident since a 2005 explosion at a BP American refinery in Texas killed 15 people and injured another 170.The Good Friday holiday blast rattled windows more than a mile away and has the most recorded fatalities since 15 workers were killed in a BP Plc incident in 2005 at that company’s Texas City, Texas, operations.

The Tesoro incident occurred as members of a seven-person crew were cleaning a heat exchanger in a unit handling naphtha, a volatile liquid chemically similar to jet fuel, Westfall told reporters.

The blast shook houses and woke people miles away, shooting flames as high as the refinery’s tower before the blaze was extinguished about 90 minutes later.

The blast occurred in a unit that was in the dangerous process of returning to operation, turning up heat and pressure, said Tesoro spokesman Greg Wright".

CSB Chairman and CEO John Bresland said, “The CSB has eighteen ongoing investigations. Of those, seven of these accidents occurred at refineries across the country. This is a significant and disturbing trend that the refining industry needs to address immediately.”

Read the complete article in this link

Process Safety – “Aging pipe fittings and plant mismanagement – a lethal combination”

An article mentions about aging pipe fittings and mismanagement. It mentions “Even the highest specification pipe fittings will fail, if they are not backed up with competent system management and the correct hardware. Too often, flanges are expected to carry more than their fair share of responsibility in preventing leaks and accidents”.

I have investigated a number of incidents where this exact reason has been the cause of a failure. This is a disturbing trend and it will help if plant management revisit their mechanical integrity program.

Read more of the article in this link

I have investigated a number of incidents where this exact reason has been the cause of a failure. This is a disturbing trend and it will help if plant management revisit their mechanical integrity program.

Read more of the article in this link

Process Safety – Shades of Bhopal?

“Bayer CropScience has agreed to pay a $143,000 fine to resolve safety citations stemming from a fatal explosion at its Institute plant in 2008.

A congressional committee report said the explosion came close to compromising a tank holding methyl isocyanate, or MIC. An MIC leak from a former Union Carbide plant in Bhopal, India, in 1984 killed thousands of people.

Union Carbide once operated the West Virginia plant, now owned by Bayer CropScience. MIC is used in the manufacture of insecticides at four different units at the sprawling 465-acre plant. One unit, the methomyl unit, was damaged in the explosion”.

Read the full article in this link

A congressional committee report said the explosion came close to compromising a tank holding methyl isocyanate, or MIC. An MIC leak from a former Union Carbide plant in Bhopal, India, in 1984 killed thousands of people.

Union Carbide once operated the West Virginia plant, now owned by Bayer CropScience. MIC is used in the manufacture of insecticides at four different units at the sprawling 465-acre plant. One unit, the methomyl unit, was damaged in the explosion”.

Read the full article in this link

March 31, 2010

Process Safety - Storage tanks

An EPA study covering a ten-year period (1990 - 2000)reveals that of the 312 accidents at tank farms examined in this period it was found that operator error accounted for 22%. Additionally, 55% were attributable to tank failure, 10% to valve failure, 4% to pump failure and 3% to bolted fitting failure. Human error also accounted for 100% of accidents that resulted in fatalities, 88% involving stock loss and 87% of property damage, with the root cause attributed to overfilling/over-pressurisation.

Storage tanks fail due to a number of reasons including collapse due to vacuum,human error, poor maintenance, vapour ignition, settlement, earthquake,lightening and over-pressurisation.

Make sure your operators are trained in the safe operation of storage tanks.

Storage tanks fail due to a number of reasons including collapse due to vacuum,human error, poor maintenance, vapour ignition, settlement, earthquake,lightening and over-pressurisation.

Make sure your operators are trained in the safe operation of storage tanks.

March 26, 2010

Process safety - learn from these incidents

The Karnataka Department of Factories, Boilers and Industrial safety and health has posted accidents that have occurred in their state.

Four incidents are posted:

1. Confined space incident

2. Incompatible material incident

3. Accident in Urea plant

4. Toxic gas release in bulk drug manufacturing.

The details are available in this link. Please circulate to all your colleagues as the incidents can happen anywhere.

Some more accidents are given in a pdf file (large file) in this link

Four incidents are posted:

1. Confined space incident

2. Incompatible material incident

3. Accident in Urea plant

4. Toxic gas release in bulk drug manufacturing.

The details are available in this link. Please circulate to all your colleagues as the incidents can happen anywhere.

Some more accidents are given in a pdf file (large file) in this link

Process Safety and Emergency Preparedness

I was reading about the two recent incidents of fires in high rise buildings in Bangalore and Kolkata and the high number of fatalities involved. In both cases, emergency escape paths were either blocked or locked. In a chemical plant emergency, things are much worse - domino effects can have catastrophic effects.Events will snowball quickly and unless you are well prepared, it will be difficult to handle a major emergency. All plant personnel should understand that mock drills are conducted when there is no emergency.In an actual emergency, Murphy's law will apply: "Anything that can go wrong will go wrong". A mock drill mentally prepares you for the do's and dont's.

Plant operating and maintenance personnel, especially those on shift duty must always keep themselves familiar about emergency alarm activation, escape paths, emergency breathing air escape packs and self contained breathing apparatus, crash shutdown procedures,emergency communication systems, what to do in total power failure and other possible emergencies.Most of the emergencies uncannily happen in the early morning hours when all shift people are sleepy and the general shift people are sleeping!

In some of the chemical units that I visit, the people assume that emergency preparedness is the job of the safety officer!If you want to survive in an emergency, YOU have to take responsibility and be prepared. Do not think it will not happen to you.You will not have a second chance.

Plant operating and maintenance personnel, especially those on shift duty must always keep themselves familiar about emergency alarm activation, escape paths, emergency breathing air escape packs and self contained breathing apparatus, crash shutdown procedures,emergency communication systems, what to do in total power failure and other possible emergencies.Most of the emergencies uncannily happen in the early morning hours when all shift people are sleepy and the general shift people are sleeping!

In some of the chemical units that I visit, the people assume that emergency preparedness is the job of the safety officer!If you want to survive in an emergency, YOU have to take responsibility and be prepared. Do not think it will not happen to you.You will not have a second chance.

March 23, 2010

Process safety - 5 Years after the BP incident

On March 23rd, 2005, the worst industrial accident in the US for more than a decade occurred at the BP Texas refinery. 5 years after the incident a news article mentions the following:

“Since the disaster, the company has spent more than $1 billion on improvements at the refinery, and continues to invest more. It's spent another $1 billion or so settling about 1,000 civil lawsuits filed by the more than 170 workers injured in the blast and by families of the dead.

“Those systems require constant vigilance. You start to think you've got it fixed, and eventually you start to focus on other things. If you let your focus wander too far, you're system starts to slip without your realizing it.”

“The U.S. Chemical Safety and Hazard Investigation Board found in 2007 that the explosion resulted from a lethal combination of cost-cutting, a lack of investment in training and mechanical systems and a lack of vigilance in maintaining safety procedures. The company has implemented sweeping changes in process safety procedures and revamped how it operates refineries. Many of those changes have been adopted by BP's rivals as well.”

“The question that continues to dog BP and the refining industry: Has it done enough?It has rejected, for example, a Chemical Safety board recommendation that it add a process safety expert to its board of directors.”

“It took the explosion,” said Gary Beevers, international vice president for the United Steelworkers union, which represents more than 1,000 workers at the refinery. “As this industry has shown, it takes something terrible for changes to happen.”

My own observation of any big incident like this is that immediately after the incident there are a lot of things done. But the question is the sustainability of these actions. Time and again I have seen that unfortunately history tends to repeat itself unless top leadership are really and continuously committed to process safety.More and more boards of Chemical and refining companies are filled up with non technical persons, with the result that there is no one at the board level to explain to the board the repercussions of cost cutting without a proper assessment.

Read the whole article in this link

“Since the disaster, the company has spent more than $1 billion on improvements at the refinery, and continues to invest more. It's spent another $1 billion or so settling about 1,000 civil lawsuits filed by the more than 170 workers injured in the blast and by families of the dead.

“Those systems require constant vigilance. You start to think you've got it fixed, and eventually you start to focus on other things. If you let your focus wander too far, you're system starts to slip without your realizing it.”

“The U.S. Chemical Safety and Hazard Investigation Board found in 2007 that the explosion resulted from a lethal combination of cost-cutting, a lack of investment in training and mechanical systems and a lack of vigilance in maintaining safety procedures. The company has implemented sweeping changes in process safety procedures and revamped how it operates refineries. Many of those changes have been adopted by BP's rivals as well.”

“The question that continues to dog BP and the refining industry: Has it done enough?It has rejected, for example, a Chemical Safety board recommendation that it add a process safety expert to its board of directors.”

“It took the explosion,” said Gary Beevers, international vice president for the United Steelworkers union, which represents more than 1,000 workers at the refinery. “As this industry has shown, it takes something terrible for changes to happen.”

My own observation of any big incident like this is that immediately after the incident there are a lot of things done. But the question is the sustainability of these actions. Time and again I have seen that unfortunately history tends to repeat itself unless top leadership are really and continuously committed to process safety.More and more boards of Chemical and refining companies are filled up with non technical persons, with the result that there is no one at the board level to explain to the board the repercussions of cost cutting without a proper assessment.

Read the whole article in this link

March 21, 2010

Boiler burst - cause of incident at NFL?

Please see news item from Tribune, Chandigarh:

NFL tragedy

Ropar admn not informed in time

Megha Mann

Tribune News Service

Nangal, March 20

While the boiler at ammonia plant burst at around 11:40 am today, district administration Ropar was informed after 40 to 50 minutes of the incidence.

Confirming this, deputy commissioner Priyank Bharti said that even area SDM Lakhmir Singh was not informed immediately after the incidence.

“As per the protocol, the NFL authorities should have informed us within minutes after the incidence. But it took at least 40 to 50 minutes for the news to reach us. Fortunately, there was no ammonia leakage. Had it been a gas leakage, more damage could have been caused and informing us untimely could have added to chaos,” he observed.

However, official spokesperson NFL Naya Nangal claimed that the SDM and DSP were informed within 15 minutes of tragedy.Sources said that injured Umesh Kumar’s timely action of switching off main gas connection helped in saving many lives. Had the ammonia spread around, more losses of life and property would have happened.

The plant, where tragedy struck, was to be closed on Monday for 25 days maintenance practice. Annual target of NFL for urea production was 4. 78 lac tonnes and NFL had already attained 4.73 lac tonnes production.Daily production of ammonia at the plant is 900 tonnes, while that of urea is 1450 tonnes. NFL spokesperson said that company would meet its target with the help of other units. The unit has been shut down three days before the scheduled time due to accident.

Nangal MLA Rana KP Singh too reached the spot. He held the NFL management responsible for this tragedy and demanded a high level probe. He said that the fire fighting equipments at factory were not up-to-date. SSP L K Yadav asked people not to panic as the accident was result of some technical failure.

NFL tragedy

Ropar admn not informed in time

Megha Mann

Tribune News Service

Nangal, March 20

While the boiler at ammonia plant burst at around 11:40 am today, district administration Ropar was informed after 40 to 50 minutes of the incidence.

Confirming this, deputy commissioner Priyank Bharti said that even area SDM Lakhmir Singh was not informed immediately after the incidence.

“As per the protocol, the NFL authorities should have informed us within minutes after the incidence. But it took at least 40 to 50 minutes for the news to reach us. Fortunately, there was no ammonia leakage. Had it been a gas leakage, more damage could have been caused and informing us untimely could have added to chaos,” he observed.

However, official spokesperson NFL Naya Nangal claimed that the SDM and DSP were informed within 15 minutes of tragedy.Sources said that injured Umesh Kumar’s timely action of switching off main gas connection helped in saving many lives. Had the ammonia spread around, more losses of life and property would have happened.

The plant, where tragedy struck, was to be closed on Monday for 25 days maintenance practice. Annual target of NFL for urea production was 4. 78 lac tonnes and NFL had already attained 4.73 lac tonnes production.Daily production of ammonia at the plant is 900 tonnes, while that of urea is 1450 tonnes. NFL spokesperson said that company would meet its target with the help of other units. The unit has been shut down three days before the scheduled time due to accident.

Nangal MLA Rana KP Singh too reached the spot. He held the NFL management responsible for this tragedy and demanded a high level probe. He said that the fire fighting equipments at factory were not up-to-date. SSP L K Yadav asked people not to panic as the accident was result of some technical failure.

Process Safety - Blast in ammonia plant

On Saturday, a blast was reported in the ammonia plant of the Nangal fertiliser plant.

It is reported that the saturator tower fell down as a result of the blast. Three people lost their lives and my heart goes out to the bereaved families. A news item in the Hindustan Times indicates that the incident took place at 1140 hrs in the shift conversion section. The gas in the shift conversion section in an ammonia plant will primarily consist of hydrogen.

It is reported that the saturator tower fell down as a result of the blast. Three people lost their lives and my heart goes out to the bereaved families. A news item in the Hindustan Times indicates that the incident took place at 1140 hrs in the shift conversion section. The gas in the shift conversion section in an ammonia plant will primarily consist of hydrogen.

March 20, 2010

Process Safety - Phosgene hose leak update

A news article on the EPA investigation of the phosgene hose leak at DuPont's Belle, US facility in January 2010,indicate the following:

1. "This type of hose should be replaced every two months "due to the extremely hazardous nature of phosgene," EPA said. At the time of the Belle plant leak, the hose had been in use for seven months.The hose was 5 months overdue for replacement"

2. "The flexible, braided-steel hose was also the wrong kind of equipment to use in the first place because of the extremely hazardous nature of phosgene"

3."EPA also said that this type of hose should be installed within six months of its fabrication. This particular hose was fabricated in May 2008, but was not installed by DuPont until June 2009".

DuPont is world renowned for their high safety standards and I wonder what went wrong.

Read the full article in this link

1. "This type of hose should be replaced every two months "due to the extremely hazardous nature of phosgene," EPA said. At the time of the Belle plant leak, the hose had been in use for seven months.The hose was 5 months overdue for replacement"

2. "The flexible, braided-steel hose was also the wrong kind of equipment to use in the first place because of the extremely hazardous nature of phosgene"

3."EPA also said that this type of hose should be installed within six months of its fabrication. This particular hose was fabricated in May 2008, but was not installed by DuPont until June 2009".

DuPont is world renowned for their high safety standards and I wonder what went wrong.

Read the full article in this link

Process safety and societal risks in India

I was going through a risk assessment report prepared for an organization that was planning to increase production capacity using a toxic chemical as a raw material. This chemical is received through pipelines traversing through public areas. I found one thing startlingly out of place. The report used outdated population data in the vicinity of the pipelines. Unauthorized settlements were everywhere near the pipeline and this was not considered in the report. This is a peculiar problem in India. How can we rely on population statistics when the data itself is dynamic on a day to day basis! One other thing that always perturbs me is that I doubt if the user of the report understands the assumptions made and is really able to understand the report.

Just having a colorful report with a lot of drawings indicating toxic end points and red zones does not really mean you have identified the risks involved.While such reports are mandatory from a regulatory perspective, it is better that the organization revisit these reports periodically based on changes in population density.

Lord Tony Newton,independent chair of the Buncefield Investigation Board says "The system should in future consider the total population at risk – societal risk – at each new development application. We should not continue to allow surrounding populations to increase without considering the consequences". I really do not know how we can implement this in India unless there is strong enforcement by the regulatory agencies.

Just having a colorful report with a lot of drawings indicating toxic end points and red zones does not really mean you have identified the risks involved.While such reports are mandatory from a regulatory perspective, it is better that the organization revisit these reports periodically based on changes in population density.

Lord Tony Newton,independent chair of the Buncefield Investigation Board says "The system should in future consider the total population at risk – societal risk – at each new development application. We should not continue to allow surrounding populations to increase without considering the consequences". I really do not know how we can implement this in India unless there is strong enforcement by the regulatory agencies.

March 17, 2010

Process safety and fatigue

It is disturbing to note that fatigue probably played a part in the new US power plant explosion that occurred when lines were being blown with natural gas. It appears that one of the victims who died in the explosion was working 12 hours a day, seven days a week, for six months. If operators are being allowed to work without break even in the US, imagine the plight in India!The pressure of commissioning a plant to meet target deadlines often result in people working overtime. With more and more activities being outsourced, industry must be careful that this problem is tackled to avoid incidents. What is more worrying is that the aviation industry in India is reporting incidents of pilot fatigue due to inadequate rest periods.If it can happen in the aviation industry, it can happen in the chemical industry too!

March 11, 2010

Process safety -Pressure Relief and Flame out devices - Take care of them!

According to a news release dated 8.3.2010, "The U.S. Department of Labor's Occupational Safety and Health Administration has cited BP North American Inc. and BP-Husky Refining LLC's refinery in Oregon, Ohio, with 42 alleged willful violations, including 39 on a per-instance basis, and 20 alleged serious violations for exposing workers to a variety of hazards including failure to provide adequate pressure relief for process units. Proposed penalties total $3,042,000.Forty-two willful citations with proposed penalties totaling $2,940,000 are proposed as follows:

1. Thirty-eight (38) per-instance, willful citations with penalties totaling $2,660,000 allege as follows:

1. Twenty-six instances allege deficient pressure relief, a violation of 29 CFR parts 1910.119(d)(3) and 1910.119(j)(5), with total penalties of $1,820,000;

2. Three instances allege the lack of flame-out protection on heaters and a furnace, a violation of 29 CFR 1910.119(d)(3), with total penalties of $210,000; and

3. Nine instances allege facility-siting hazards, a violation of 29 CFR 1910.119(e)(5), with total penalties of $630,000.

2. Four willful citations with penalties totaling $280,000, allege as follows:

1. Lack of pressure vessel information, a violation of 29 CFR 1910.119(d)(3), with a penalty of $70,000;

2. Cross-connections between fire-emergency water supplies and process systems, a violation of 29 CFR parts 1910.119(d)(3) and 1910.119(e)(5), with a penalty of $70,000;

3. Failure to conduct thickness measurements at designated test sites and as required at the flare header, a violation of 29 CFR 1910.119(j)(4)(ii), with a penalty of $70,000; and

4. Failure to conduct thickness measurements in accordance with RAGAGEP, a violation of 29 CFR 1910.119(j)(4)(iii), with a penalty of $70,000".

Of particular interest is the twenty six instances of deficient pressure relief and three instances of lack of flame out protection.

1. Thirty-eight (38) per-instance, willful citations with penalties totaling $2,660,000 allege as follows:

1. Twenty-six instances allege deficient pressure relief, a violation of 29 CFR parts 1910.119(d)(3) and 1910.119(j)(5), with total penalties of $1,820,000;

2. Three instances allege the lack of flame-out protection on heaters and a furnace, a violation of 29 CFR 1910.119(d)(3), with total penalties of $210,000; and

3. Nine instances allege facility-siting hazards, a violation of 29 CFR 1910.119(e)(5), with total penalties of $630,000.

2. Four willful citations with penalties totaling $280,000, allege as follows:

1. Lack of pressure vessel information, a violation of 29 CFR 1910.119(d)(3), with a penalty of $70,000;

2. Cross-connections between fire-emergency water supplies and process systems, a violation of 29 CFR parts 1910.119(d)(3) and 1910.119(e)(5), with a penalty of $70,000;

3. Failure to conduct thickness measurements at designated test sites and as required at the flare header, a violation of 29 CFR 1910.119(j)(4)(ii), with a penalty of $70,000; and

4. Failure to conduct thickness measurements in accordance with RAGAGEP, a violation of 29 CFR 1910.119(j)(4)(iii), with a penalty of $70,000".

Of particular interest is the twenty six instances of deficient pressure relief and three instances of lack of flame out protection.

March 8, 2010

Purging of Natural Gas Lines - Adding fuel to the fire?

The CSB had issued urgent recommendations on the natural gas explosion at Con Agra on June 9,2009. The incident occurred when natural gas lines were being purged free of air using natural gas itself.The CSB urgent recommendations include

(a) Purged fuel gases shall be directly vented to a safe location outdoors, away from personnel and ignition sources

(b) If it is not possible to vent purged gases outdoors, purging gas to the inside of a building shall be allowed only upon approval by the authority having jurisdiction of a documented risk evaluation and hazard control plan.The evaluation and plan shall establish that indoor purging is necessary and that adequate safeguards are in place such as:

• Evacuating nonessential personnel from the vicinity of the purging;

• Providing adequate ventilation to maintain the gas concentration at an established safe level, substantially below the lower explosive limit; and

• Controlling or eliminating potential ignition sources

(c) Combustible gas detectors are used to continuously monitor the gas concentration at appropriate locations in the vicinity where purged gases are released

(d) Personnel are trained about the problems of odor fade and odor fatigue and warned against relying on odor alone for detecting releases of fuel gases

It is not safe in the first place to allow purging of an air filled pipeline with natural gas. You can never control or eliminate all potential ignition sources. PERIOD!!

See the CSB recommendations in this link.

See my latest post on this subject

(a) Purged fuel gases shall be directly vented to a safe location outdoors, away from personnel and ignition sources

(b) If it is not possible to vent purged gases outdoors, purging gas to the inside of a building shall be allowed only upon approval by the authority having jurisdiction of a documented risk evaluation and hazard control plan.The evaluation and plan shall establish that indoor purging is necessary and that adequate safeguards are in place such as:

• Evacuating nonessential personnel from the vicinity of the purging;

• Providing adequate ventilation to maintain the gas concentration at an established safe level, substantially below the lower explosive limit; and

• Controlling or eliminating potential ignition sources

(c) Combustible gas detectors are used to continuously monitor the gas concentration at appropriate locations in the vicinity where purged gases are released

(d) Personnel are trained about the problems of odor fade and odor fatigue and warned against relying on odor alone for detecting releases of fuel gases

It is not safe in the first place to allow purging of an air filled pipeline with natural gas. You can never control or eliminate all potential ignition sources. PERIOD!!

See the CSB recommendations in this link.

See my latest post on this subject

March 5, 2010

Domino effect and Process Safety

An interesting article on Domino Effects in the developed countries mentions the following "A study of 261 accidents involving domino effect has been carried out. The main features have been analyzed: origin, causes, consequences and most frequent sequences. The analysis has shown that the most frequent causes are external events (31%) and mechanical failure (30%). The storage areas (37%) and process plants (27%) are by far the most common places where domino accidents have occurred. The most common sequence in the event trees resulted to be explosion–fire (21%), followed by release– fire–explosion (15%) and fire–explosion (14%)".

While the study concludes that "The historical analysis has shown that the frequency of domino effect accidents has decreased over the last two decades. Most of these accidents have occurred –as could be expected– in the most industrialized countries (from which, furthermore, more information is available). The most frequent sequences are explosion–fire, release–fire– explosion and fire–explosion. From the analysis of the causes, although the most frequent ones are external events and mechanical failure, a relatively high frequency is found for human error. This would indicate the need to further promote the training of employees, as well as an additional improvement of safety measures, specially in storage areas".

As more and more chemical industries are coming up in India, it becomes very important to study facility siting issues.Incidents like the Jaipur fire clearly indicate the need for a stronger implementation of facility siting rules.

Read the whole article in this link.

While the study concludes that "The historical analysis has shown that the frequency of domino effect accidents has decreased over the last two decades. Most of these accidents have occurred –as could be expected– in the most industrialized countries (from which, furthermore, more information is available). The most frequent sequences are explosion–fire, release–fire– explosion and fire–explosion. From the analysis of the causes, although the most frequent ones are external events and mechanical failure, a relatively high frequency is found for human error. This would indicate the need to further promote the training of employees, as well as an additional improvement of safety measures, specially in storage areas".

As more and more chemical industries are coming up in India, it becomes very important to study facility siting issues.Incidents like the Jaipur fire clearly indicate the need for a stronger implementation of facility siting rules.

Read the whole article in this link.

March 2, 2010

Dangers of melting contents of drums

A chemical manufacturer in India has been asked to pay to pay $8.37 million for a fire that destroyed a Houston-based pesticides maker's warehouse and offices in Pasadena six years ago.