It is good to note that a Civil Aviation Authority is being set up by the Govt. to address safety issues in aviation.As per a news article, "the proposed CAA, which would have administrative and financial autonomy, is also likely to keep a tab on the entire range of activities —from proper provision of air traffic services and licensing to financial fitness of airlines.Government plans to bring in a legislation to establish the CAA. Bhushan said the CAA would have a "lot of financial, administrative and procedural independence. We will be able to recruit (professionals) directly" instead of routing it through the Union Public Service Commission".

On a similar line, it would be good if a Chemical Safety Authority on the lines of the Chemical Safety Board of the USA is set up in India. Read the article about the Civil Aviation Authority in this link.

April 2, 2011

April 1, 2011

Inferno at German oil refinery

Thanks to Abhay Gujar for sending information on a major fire in a ship which was being loaded with gasoline in Germany. The article mentions the following:

"A police spokesman in the town of Lingen an der Ems, in the northwestern state of Lower Saxony, confirmed a series of massive explosions rocked the ship near an oil refinery on the Dortmund-Ems canal where the ship was being loaded late on Monday evening. A significant amount of fuel leaked out, with firefighters spending hours trying to tackle the blaze. Eventually, they brought the flames under control, preventing them from spreading to fully-loaded tankers nearby. All five crew members on the ship escaped the inferno, according to police, although one of the men suffered minor injuries".

Read the article and see photos in this link.

"A police spokesman in the town of Lingen an der Ems, in the northwestern state of Lower Saxony, confirmed a series of massive explosions rocked the ship near an oil refinery on the Dortmund-Ems canal where the ship was being loaded late on Monday evening. A significant amount of fuel leaked out, with firefighters spending hours trying to tackle the blaze. Eventually, they brought the flames under control, preventing them from spreading to fully-loaded tankers nearby. All five crew members on the ship escaped the inferno, according to police, although one of the men suffered minor injuries".

Read the article and see photos in this link.

March 27, 2011

The importance of correct measurement in Process Safety

In February 2008, a stealth bomber of the US airforce crashed soon after take off. The pilots ejected safely but the loss was USD 1.4 billion. Wikepedia mentions the following about the cause for the crash...

"The findings of the investigation stated that the B-2 crashed after "heavy, lashing rains" caused water to enter skin-flush air-data sensors, which feed data to the computerized flight-control system. The water distorted preflight readings in three of the plane's 24 sensors, causing the flight-control system to send an erroneous correction to the B-2 on takeoff. The B-2 quickly stalled, became unrecoverable, and crashed. The sensors in question measure numerous environmental factors, including air pressure and density, for data to calculate airspeed, altitude and attitude. Because of the faulty readings, the flight computers determined inaccurate airspeed readings and incorrectly indicated a downward angle for the aircraft, which contributed to an early rotation and an un-commanded 30-degree pitch up and left yaw, resulting in the stall"

Whatever advanced process control systems you may have, it ultimately depends on the measurement reading that the system receives. Focus on the integrity of your primary measuring devices.

Read the article about the crash in this link.

"The findings of the investigation stated that the B-2 crashed after "heavy, lashing rains" caused water to enter skin-flush air-data sensors, which feed data to the computerized flight-control system. The water distorted preflight readings in three of the plane's 24 sensors, causing the flight-control system to send an erroneous correction to the B-2 on takeoff. The B-2 quickly stalled, became unrecoverable, and crashed. The sensors in question measure numerous environmental factors, including air pressure and density, for data to calculate airspeed, altitude and attitude. Because of the faulty readings, the flight computers determined inaccurate airspeed readings and incorrectly indicated a downward angle for the aircraft, which contributed to an early rotation and an un-commanded 30-degree pitch up and left yaw, resulting in the stall"

Whatever advanced process control systems you may have, it ultimately depends on the measurement reading that the system receives. Focus on the integrity of your primary measuring devices.

Read the article about the crash in this link.

March 26, 2011

Bayer stops MIC production

A news article mentions the following:

"In a surprise move in U.S. District Court in Charleston, attorneys for Bayer CropScience announced they were dropping plans to resume production of the chemical, commonly called MIC, and would begin dismantling the unit.

That ends the key part of the latest lawsuit in a nearly three-decade battle.But Bayer's decision erases a threat that loomed over the people of Institute for a generation.

The company will no doubt replace MIC, which is used to make a pesticide, with some other chemical, but nothing could be as bad, said Oden, a retired biology professor at West Virginia State University who still lives next to the plant."Chemicals don't have to kill," she said.

"There were so many questions that weren't answered," she said. "And I know there' no such thing as foolproof, because look at the situation in Japan. There's no safe, foolproof ways for doing most of what we do."

A 2008 accident that killed two workers and sent projectiles dangerously close to an aboveground MIC storage tank brought new scrutiny from Congress and the U.S. Chemical Safety Board.

The explosion also showed larger, more affluent communities in the Kanawha Valley that they too could be in danger — towns that the folks in Institute can't help but notice are whiter. In all, some 300,000 people live in the 25-mile MIC "vulnerability zone," which includes the state capital.

MIC is a colorless chemical used to make pesticides, polyurethane foam and plastics. It attacks the respiratory system, and at low levels, can irritate the eyes and throat. High concentrations can cause serious lung damage, hemorrhaging and death.

Several companies manufacture it, but the Institute plant is the only one in the nation that still stores it in large quantities.

Bayer has said it spent $36 million to improve safety and upgrade equipment, and that it slashed its MIC stockpile by 80 percent and eliminated all aboveground storage. How long it will take to exhaust the remaining supply and rid Institute of MIC entirely was not immediately clear.

Less than two years after Bhopal, Congress passed the federal Right-to-Know Act, to help the thousands of people around the country who live in the shadow of industry know what chemicals are made and stored in their neighborhoods. But that openness began to diminish after the terrorist attacks of 2001. Chemical plants became viewed as potential targets. Reports on the toxic inventory of industries were no longer as readily available to the public.

Read the full article in this link

"In a surprise move in U.S. District Court in Charleston, attorneys for Bayer CropScience announced they were dropping plans to resume production of the chemical, commonly called MIC, and would begin dismantling the unit.

That ends the key part of the latest lawsuit in a nearly three-decade battle.But Bayer's decision erases a threat that loomed over the people of Institute for a generation.

The company will no doubt replace MIC, which is used to make a pesticide, with some other chemical, but nothing could be as bad, said Oden, a retired biology professor at West Virginia State University who still lives next to the plant."Chemicals don't have to kill," she said.

"There were so many questions that weren't answered," she said. "And I know there' no such thing as foolproof, because look at the situation in Japan. There's no safe, foolproof ways for doing most of what we do."

A 2008 accident that killed two workers and sent projectiles dangerously close to an aboveground MIC storage tank brought new scrutiny from Congress and the U.S. Chemical Safety Board.

The explosion also showed larger, more affluent communities in the Kanawha Valley that they too could be in danger — towns that the folks in Institute can't help but notice are whiter. In all, some 300,000 people live in the 25-mile MIC "vulnerability zone," which includes the state capital.

MIC is a colorless chemical used to make pesticides, polyurethane foam and plastics. It attacks the respiratory system, and at low levels, can irritate the eyes and throat. High concentrations can cause serious lung damage, hemorrhaging and death.

Several companies manufacture it, but the Institute plant is the only one in the nation that still stores it in large quantities.

Bayer has said it spent $36 million to improve safety and upgrade equipment, and that it slashed its MIC stockpile by 80 percent and eliminated all aboveground storage. How long it will take to exhaust the remaining supply and rid Institute of MIC entirely was not immediately clear.

Less than two years after Bhopal, Congress passed the federal Right-to-Know Act, to help the thousands of people around the country who live in the shadow of industry know what chemicals are made and stored in their neighborhoods. But that openness began to diminish after the terrorist attacks of 2001. Chemical plants became viewed as potential targets. Reports on the toxic inventory of industries were no longer as readily available to the public.

Read the full article in this link

March 25, 2011

"A Fail safe fails"

A news item in the The Wall street Journal reports the following:

"BP PLC came within 1.4 inches or less of preventing the worst offshore oil spill in U.S. history, say engineers studying the safety device that failed in last year's Gulf of Mexico disaster.

The device, known as a blowout preventer, was a massive set of valves that sat on the sea floor nearly a mile beneath the Deepwater Horizon drilling rig, which floated on the surface. It was equipped with powerful shears designed to cut through pipe and seal off the well in an emergency. Why the device failed has been one of the central mysteries of last year's disaster.

In a report released Wednesday, engineers hired by U.S. investigators say they have solved it: The force of the blowout bent the drill pipe, knocking it off-center and jamming the shears. Rather than seal the well, the blades got stuck 1.4 inches or less apart, leaving plenty of space for 4.9 million barrels of oil to leak out.

The investigators concluded the blowout preventer failed as a result of a design flaw, not because of misuse by BP or any of the other companies involved, and not because of poor maintenance. The fail-safe device, the last line of defense against a disaster, wasn't designed to handle a real-world blowout, according to investigators, who called for further study of the devices.

The report doesn't address what caused the blowout itself. That has been the subject of several other major inquiries, which all have found that a series of decisions by BP and its contractors set the disaster in motion.

Even if the device had worked, it wouldn't have saved the lives of the 11 rig workers killed in the accident. That's because no one even tried to activate the shears until after massive explosions killed the men and crippled the rig. But the device could have mostly prevented the oil spill that began when the Deepwater Horizon sank two days after the initial explosion".

How sure are you that your fail safe devices will work as intended? Today there are systems available to conduct a online partial stroke test of critical valves. But the test is done during normal operating conditions. In the case of a major upset or incident, conditions may prevent the fail safe devices from working.

Read the article in this link.

"BP PLC came within 1.4 inches or less of preventing the worst offshore oil spill in U.S. history, say engineers studying the safety device that failed in last year's Gulf of Mexico disaster.

The device, known as a blowout preventer, was a massive set of valves that sat on the sea floor nearly a mile beneath the Deepwater Horizon drilling rig, which floated on the surface. It was equipped with powerful shears designed to cut through pipe and seal off the well in an emergency. Why the device failed has been one of the central mysteries of last year's disaster.

In a report released Wednesday, engineers hired by U.S. investigators say they have solved it: The force of the blowout bent the drill pipe, knocking it off-center and jamming the shears. Rather than seal the well, the blades got stuck 1.4 inches or less apart, leaving plenty of space for 4.9 million barrels of oil to leak out.

The investigators concluded the blowout preventer failed as a result of a design flaw, not because of misuse by BP or any of the other companies involved, and not because of poor maintenance. The fail-safe device, the last line of defense against a disaster, wasn't designed to handle a real-world blowout, according to investigators, who called for further study of the devices.

The report doesn't address what caused the blowout itself. That has been the subject of several other major inquiries, which all have found that a series of decisions by BP and its contractors set the disaster in motion.

Even if the device had worked, it wouldn't have saved the lives of the 11 rig workers killed in the accident. That's because no one even tried to activate the shears until after massive explosions killed the men and crippled the rig. But the device could have mostly prevented the oil spill that began when the Deepwater Horizon sank two days after the initial explosion".

How sure are you that your fail safe devices will work as intended? Today there are systems available to conduct a online partial stroke test of critical valves. But the test is done during normal operating conditions. In the case of a major upset or incident, conditions may prevent the fail safe devices from working.

Read the article in this link.

March 23, 2011

Explosion in carbide plant

The CSB is planning to investigate an explosion in a carbide plant in the US, that occurred on Tuesday. Two employees were killed in the incident. A news report mentions that

"Located along the Ohio River in West Louisville, the plant is part of a petrochemical complex dubbed Rubbertown. It makes calcium carbide products, which are used in metal fabrication and construction.

The initial explosion occurred around 5:40 p.m. Monday and involved calcium-carbide — a flammable compound that combined with water produces unstable acetylene gas, Hamilton said. The second explosion happened when one of three transformers that contained mineral oil above the original blast caught fire, officials said."

The workers who died were longtime employees who worked in the furnace department where the explosion occurred, said plant general manager John Gant. Jorge Medina, 56, of Louisville, died at University Hospital early Tuesday morning with third-degree burns over 90 percent of his body. An autopsy is planned for Steven Nicholas, 59, of Charlestown, Ind., who died Monday".

"Located along the Ohio River in West Louisville, the plant is part of a petrochemical complex dubbed Rubbertown. It makes calcium carbide products, which are used in metal fabrication and construction.

The initial explosion occurred around 5:40 p.m. Monday and involved calcium-carbide — a flammable compound that combined with water produces unstable acetylene gas, Hamilton said. The second explosion happened when one of three transformers that contained mineral oil above the original blast caught fire, officials said."

The workers who died were longtime employees who worked in the furnace department where the explosion occurred, said plant general manager John Gant. Jorge Medina, 56, of Louisville, died at University Hospital early Tuesday morning with third-degree burns over 90 percent of his body. An autopsy is planned for Steven Nicholas, 59, of Charlestown, Ind., who died Monday".

Read the article in this link.

See video and pictures of the accident in this link

March 22, 2011

Fire in lift kills two persons

Thanks to Mr Sreedharan for sending information about a fire accident in a plant when two workers died in a fire in a lift when they were carrying combustible material. According to the news item, "the workers were carrying improperly packed medicine ‘CBS' which released a vapour which is combustible in nature. The vapour released was in large quantity leading to fire in the lift burning them alive. By the time the other workers in the factory arrived and tried to out the fire, both the casual workers were burnt alive".

Read the article in this link

I had earlier posted an incident where a lab technician in a plant (the Lab was located in the control room building) was taking a bottle of solvent and using the lift (elevator) when he accidentally dropped the bottle. The solvent went down the elevators floor and collected in the well. A spark ignited the solvent and the person had to be rescued from the elevator.

Read the article in this link

I had earlier posted an incident where a lab technician in a plant (the Lab was located in the control room building) was taking a bottle of solvent and using the lift (elevator) when he accidentally dropped the bottle. The solvent went down the elevators floor and collected in the well. A spark ignited the solvent and the person had to be rescued from the elevator.

How do we make PSM work in India?

PSM is an administrative control over process safety. The elements may vary from 14 to 30 and above but finally it is an administrative control. Human beings take decisions that can have an effect on PSM. For example, the CSB has released the safety video of the Bayer Crop science explosion where it mentions an interlock was bypassed by operators with the knowledge of the manager. Whatever systems you have, there will be a time, when under pressure for production, mistakes can happen and the administrative control fails. Behaviour based safety, developing process safety culture, operational discipline all are dependent on the Human Being. Especially the ones at the top…

Why do the same mistakes keep happening over and over again? It’s because of a basic human trait ….. if nothing has happened for so many years, one does not expect to see anything bad in the future, too.

What you do not see may cost you terribly!! Whose job is it to see that the human being at the operational level does not deviate from set procedures? It’s the job of the top management. But it’s a chicken and egg situation. Today’s top management in Chemical Plants are under severe pressure themselves and often loose sight of what is going on at the ground level. Whenever a new system that brings in top management involvement is implemented, I often see, that initially, everything is working all right and top management are focused on process safety. As time gets by, and people (including top management) and priorities change, the effectiveness of PSM changes, too. I feel that the only way to make PSM work is through effective legal enforcement. In this connection, I am happy to see in the CSB video that the Costa County officials have been able to bring down incidents by effective auditing of PSM systems.

I do not see this happening in India where PSM is not even Mandatory! Let’s not wait for another Bhopal to occur. Do write in your comments.

March 21, 2011

Cost - Benefit trade off and risk

An editorial in Las Vegas Review Journal highlights the need for facility siting, inherent safer design and cost benefit trade off Vs Risk. The article mentions the following:

"It's not too early to start asking the billion-dollar questions: Is it possible to build nuclear reactors that can be relied on to safely shut themselves down, using passive cooling systems dependent on gravity rather than electric pumps, during an earthquake of such magnitude? Of the 442 nuclear reactors in operation around the world today, the World Nuclear Association estimates 20 percent are located in areas of "significant seismic activity." Siting will be re-examined. Better designs do appear possible.

One hundred percent passive cooling systems are not yet commercially available. But had even a partial passive system been in place at the Fukushima Dai-ichi plant, Japan's current nuclear crisis could have been averted, argues John McGaha, a board member of the American Nuclear Society.

"The thing that got Japan in trouble was not the earthquake, but the tsunami that took out power supplies," Mr. McGaha says. "Passive reactors would have been part of the answer to what happened."

In General Electric's design for the Fukushima reactors, the cooling tanks for storage of spent fuel rods sit atop the containment buildings. Some of these tanks appear to have gone dry, leaving the spent rods to spew radiation. If the tanks sat at or below ground level, they could be refilled by simply opening a spigot from backup water tanks, or through gravity-fed pipelines.

Meantime, the backup diesel generators that might have averted the disaster were positioned in a basement, where they were overwhelmed by the tsunami. In the end, cost-benefit trade-offs will still be made. But a valid cost-benefit analysis requires data as to what the true "costs" are when systems fail."

Read the editorial in this link..

"It's not too early to start asking the billion-dollar questions: Is it possible to build nuclear reactors that can be relied on to safely shut themselves down, using passive cooling systems dependent on gravity rather than electric pumps, during an earthquake of such magnitude? Of the 442 nuclear reactors in operation around the world today, the World Nuclear Association estimates 20 percent are located in areas of "significant seismic activity." Siting will be re-examined. Better designs do appear possible.

One hundred percent passive cooling systems are not yet commercially available. But had even a partial passive system been in place at the Fukushima Dai-ichi plant, Japan's current nuclear crisis could have been averted, argues John McGaha, a board member of the American Nuclear Society.

"The thing that got Japan in trouble was not the earthquake, but the tsunami that took out power supplies," Mr. McGaha says. "Passive reactors would have been part of the answer to what happened."

In General Electric's design for the Fukushima reactors, the cooling tanks for storage of spent fuel rods sit atop the containment buildings. Some of these tanks appear to have gone dry, leaving the spent rods to spew radiation. If the tanks sat at or below ground level, they could be refilled by simply opening a spigot from backup water tanks, or through gravity-fed pipelines.

Meantime, the backup diesel generators that might have averted the disaster were positioned in a basement, where they were overwhelmed by the tsunami. In the end, cost-benefit trade-offs will still be made. But a valid cost-benefit analysis requires data as to what the true "costs" are when systems fail."

Read the editorial in this link..

March 20, 2011

Description of some damages to the Nigata Nuclear plant in 2007 - Courtesy TEPCO

The earthquake at Nigata, Japan in 2007 was 6.9 on the Richter scale. The one that hit Fukushima was 8.9.(The Richter scale is Logarithmic!!!) See the damages caused by the Nigata earthquake...

"Displacement of the ducts connected to the main exhaust stack (units 1 to 5)'. Courtesy of The Tokyo Electric Power Company, Inc

Courtesy of The Tokyo Electric Power Company, Inc

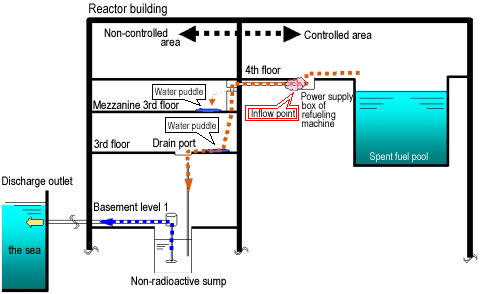

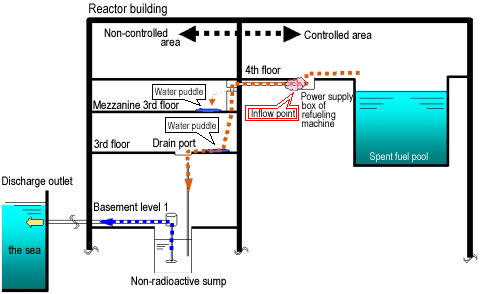

"Leakage of water containing a trace of radioactivity into the sea via the non-controlled area of unit 6.

The seismic motion caused the overflow of water from the spent fuel pools in units 1 to 7. At unit 6, the overflowed water leaked into the non-controlled area via the electric cable conduit of the refueling machine and flowed into the sump. It was confirmed that water in the drainage sump had been discharged into the sea by the sump pump when the water level increased. (Refer to the figure below".)

Courtesy of The Tokyo Electric Power Company, Inc

Courtesy of The Tokyo Electric Power Company, Inc

Iodine and radioactive particulate materials were detected at the main exhaust stack of unit 7.

"When the earthquake occurred, unit 7 was automatically shut down. However, it was confirmed that since the gland steam ventilator continued to operate for a while, the steam sealing the shaft was exhausted, and subsequently radioactive steam left in the turbine had flowed out to through the gland steam ventilator. (This event was reported on July 16th.)

During normal operation, the turbine shaft is covered with the gland steam (containing no radioactive material) so that the steam containing radioactive materials sent from the reactor to the turbine does not flow out from the turbine through the gland steam ventilator.

Impact to the Environment

The radioactivity of radioactive iodine and radioactive particulate materials released to the environment through the main exhaust stack was about 4 × 108 becquerels and 2 × 106 becquerels, respectively. The dose by this radioactivity was 2 × 10-7 millisieverts, an equivalent to about one 10 millionth of the dose (2.4 millisieverts) an average person is exposed to from natural sources annually.

No radioactive material has been detected since the gland steam ventilator was stopped on July 19th".

For more details visit the TEPCO site in this link

"Displacement of the ducts connected to the main exhaust stack (units 1 to 5)'. Courtesy of The Tokyo Electric Power Company, Inc

Courtesy of The Tokyo Electric Power Company, Inc

"Leakage of water containing a trace of radioactivity into the sea via the non-controlled area of unit 6.

The seismic motion caused the overflow of water from the spent fuel pools in units 1 to 7. At unit 6, the overflowed water leaked into the non-controlled area via the electric cable conduit of the refueling machine and flowed into the sump. It was confirmed that water in the drainage sump had been discharged into the sea by the sump pump when the water level increased. (Refer to the figure below".)

Courtesy of The Tokyo Electric Power Company, Inc

Courtesy of The Tokyo Electric Power Company, Inc

Iodine and radioactive particulate materials were detected at the main exhaust stack of unit 7.

"When the earthquake occurred, unit 7 was automatically shut down. However, it was confirmed that since the gland steam ventilator continued to operate for a while, the steam sealing the shaft was exhausted, and subsequently radioactive steam left in the turbine had flowed out to through the gland steam ventilator. (This event was reported on July 16th.)

During normal operation, the turbine shaft is covered with the gland steam (containing no radioactive material) so that the steam containing radioactive materials sent from the reactor to the turbine does not flow out from the turbine through the gland steam ventilator.

Impact to the Environment

The radioactivity of radioactive iodine and radioactive particulate materials released to the environment through the main exhaust stack was about 4 × 108 becquerels and 2 × 106 becquerels, respectively. The dose by this radioactivity was 2 × 10-7 millisieverts, an equivalent to about one 10 millionth of the dose (2.4 millisieverts) an average person is exposed to from natural sources annually.

No radioactive material has been detected since the gland steam ventilator was stopped on July 19th".

For more details visit the TEPCO site in this link

March 19, 2011

Process Safety and Proposed changes to Indian Factories act

A news article in the Business Standard mentions the proposed changes to the Indian Factories Act. There are two proposed modifications, which I think may have an effect on process safety:

"The proposed changes to Section 64 and 65 of the Act, which deal with overtime working hours in factories, says the hours will be increased to 100 from the existing 50.

The proposals also seek to shift the blame for industrial accidents from the proprietor to the manager of a factory provided it is government-owned, by changing the definition of “occupier” of the factory in Section 2 (n) from the “person who has ultimate control over affairs of a factory” to the “person appointed to manage the factory”.

Workers who are working more hours of overtime are prone to making mistakes. There is a growing shortage of experienced qualified chemical plant operators in India and the proposed increase in overtime hours may affect process safety. The second proposed change of transferring accountability for Government owned companies to the person appointed to manage the factory may lead to a situation where the unit head in a government owned factory may resign when he or she finds things are not going his/her way with regard to process safety. This will lead to a discontinuity in managing process safety.

Read the article in this link.

"The proposed changes to Section 64 and 65 of the Act, which deal with overtime working hours in factories, says the hours will be increased to 100 from the existing 50.

The proposals also seek to shift the blame for industrial accidents from the proprietor to the manager of a factory provided it is government-owned, by changing the definition of “occupier” of the factory in Section 2 (n) from the “person who has ultimate control over affairs of a factory” to the “person appointed to manage the factory”.

Workers who are working more hours of overtime are prone to making mistakes. There is a growing shortage of experienced qualified chemical plant operators in India and the proposed increase in overtime hours may affect process safety. The second proposed change of transferring accountability for Government owned companies to the person appointed to manage the factory may lead to a situation where the unit head in a government owned factory may resign when he or she finds things are not going his/her way with regard to process safety. This will lead to a discontinuity in managing process safety.

Read the article in this link.

March 16, 2011

Changes to my blog

Based on feedback from readers, I have added categories in my blog http://indiaprocesssafety.blogspot.com where u can browse the following postings:

Incidents (99)

Safe work practices (28)

BP Oil Rig Disaster (19)

Incident Investigation (19)

Organisational Culture (19)

Bhopal (17)

Emergency planning and response (15)

Mechanical integrity (15)

PSM (13)

Process design (10)

Human factors (9)

Audits (7)

Fire and explosion (7)

Runaway reactions (7)

Process safety and security (6)

Instrumentation (5)

Siting (5)

Transportation accidents (5)

LOPA (4)

Process Safety and Aviation (4)

Risk management (4)

Training (3)

Behaviour based safety (2)

Indian Regulatory (2)

Managing change (2)

Shutdown systems (2)

Vacuum hazards (2)

Alarm management (1)

Backup systems (1)

CSB Safety videos (1)

MSDS (1)

Incidents (99)

Safe work practices (28)

BP Oil Rig Disaster (19)

Incident Investigation (19)

Organisational Culture (19)

Bhopal (17)

Emergency planning and response (15)

Mechanical integrity (15)

PSM (13)

Process design (10)

Human factors (9)

Audits (7)

Fire and explosion (7)

Runaway reactions (7)

Process safety and security (6)

Instrumentation (5)

Siting (5)

Transportation accidents (5)

LOPA (4)

Process Safety and Aviation (4)

Risk management (4)

Training (3)

Behaviour based safety (2)

Indian Regulatory (2)

Managing change (2)

Shutdown systems (2)

Vacuum hazards (2)

Alarm management (1)

Backup systems (1)

CSB Safety videos (1)

MSDS (1)

Subscribe to:

Posts (Atom)